Publication Information

ISSN 2692-1529

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2019

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

The Formulation of Aqua Feed Using Locally Sourced Ingredients for Nile Tilapia in The Bahamas

Mia Avril and Megan Poulton*

Cape Eleuthera Island School Cape Eleuthera Institute, Eleuthera, The Bahamas

Received Date: October 31, 2024; Accepted Date: November 11, 2024; Published Date: November 21, 2024.

*Corresponding author: Megan Poulton, Cape Eleuthera Institute, Eleuthera, The Bahamas. Phone No.: 12423348551, Email: meganepoulton@gmail.com

Citation: Avril M and Poulton M [2024] The Formulation of Aqua Feed Using Locally Sourced Ingredients for Nile Tilapia in The Bahamas. Jr Aqua Mar Bio Eco: JAMBE-135.

DOI: 10.37722/JAMBE.2024203

Abstract

Aquafeeds account for up to 60% of production cost in aquaculture systems, and access to appropriate feeds has been identified as a major inhibitor to the expansion of the aquaculture sector in the Caribbean region. It was proposed that the ability to formulate feed locally would increase farmers’ access to reliable resources using sustainable materials. Effective substitutes to traditional aquafeed ingredients were identified within the Bahamas and used to formulate a trial pellet diet for Nile tilapia. This diet focused primarily on protein [i.e. fish offal (e.g. Nassau grouper and red snapper), spiny lobster discards, black soldier fly larvae and moringa] and carbohydrate (i.e., cassava and brewers spent grain) alternatives; however, it also included other unconventional ingredients such as sweet potato leaves. A comparative analysis was then conducted to investigate the growth and physiological performance of two tilapia strains, red hybrid (Oreochromis spp.) and white hybrid (O. niloticus x O. aureus), fed with either traditional commercial feed or the homemade feed. Experimental tanks were set up containing ten individuals of the two tilapia strains and were fed one of the two diets as follows: T1-Red hybrid x Local diet, T2- White hybrid x Local diet, T3- Red hybrid x Commercial diet, T4- White hybrid X Commercial diet. At the beginning and end of the study period, individuals from each tank were sampled for growth and health parameters including total length (cm), weight (g), girth (cm), and organ weight (liver and heart) as a percentage of body mass to calculate hepatosomatic indices (HPI) and relative ventricular mass (RVM). Over 10 weeks, a 3–5% feed ration was maintained with partial samples being conducted intermittently to determine biomass for feed calculation. Results indicate that while the white hybrid tilapia strain had a higher growth rate than the red hybrid on both diets, both strains reported higher growth rates on the homemade feed than the commercial feed. HPI and RVM were not significantly different between the two diets, suggesting that the homemade feed supports equitable fish growth and health when compared to a commercial feed. While the homemade feed during these initial trials was more expensive to produce, these preliminary results suggests that: 1) locally sourced ingredients do create an equally effective product and 2) that ‘recycling’ from waste streams of other food production ventures, such as the fishing and the brewery industries will promote more sustainable aquaculture systems for the Caribbean region and The Bahamas.

Keywords: alternative ingredients, aquafeed formulation, circular diets, sustainable aquaculture, tilapia aquaculture

Introduction

Aquaculture has been identified as the fastest growing food production sector globally [1], expanding global food security by providing nutrition, contributing to a national economic development and global food supply [2]. This growth is not reflected in the Caribbean region, where aquaculture production has declined from 1980s to present [3]. Access to affordable, good quality aquafeeds has been identified as one of the factors that hinders the growth of aquaculture in the region, and production of feeds using locally sourced ingredients has been identified as a means of addressing this issue [4].

Local feed production reduces the dependency on importation, granting more control over the sector, aiding in the longevity and resilience of the industry [5]. The value chain analysis of various aquaculture products in the region reveals a heavy focus on the production of primary products. By manufacturing locally sourced feeds that are potentially more afforable, economic opportunities can be created for all stakeholders, including producers of raw materials [5]. These incentives may attract entrants into aquaculture production and support sustainable expansion of the sector in the region.

The objective of this study is to investigate the use of alternative ingredients in aquafeed production. Applied to the Caribbean, local sources of fish feed primary ingredients of protein, carbohydrates, lipids, vitamins and minerals were investigated [6]. This was an investigation into a 100% local substitution, to explore a knowledge gap within the field, where research thus far has been on single substitute comparisons. The experiment followed the development of diets for juvenile Nile Tilapia (Oreochromis niloticus) with the trial focused on prospective ingredients, the quality of the pellet and the health and growth of the species. This experiment makes preliminary steps into a large scope discussion that has the potential to alter the aquaculture industry in the Bahamas and wider Caribbean region.

Methods

Ingredient Composition

The ingredients identified as being suitable for aquafeed formulation for this experiment were as follows: fishery discards (finfish, lobsters) [7], black soldier fly larvae [8], brewers spent grain [9, 10, 11], cassava tuber [12], cassava leaves [13], sweet potato leaves [4], moringa leaves [14,15] and soybean oil.

The fishery discards were collected from local fishermen, sterilized using a pressure cooker at 1200C for 20 minutes before being dehydrated using a ‘Cosori Food Dehydrator Machine’ at 260C for 20 hours [16]. The black soldier fly larvae were collected from composting of kitchen waste at the Cape Eleuthera Institute campus. The larvae were killed using boiling water, and then dehydrated at 630C for 24 hours [17, 18, 19]. The brewers’ spent grain was obtained from the Commonwealth Brewery in Nassau, The Bahamas, and dehydrated at 630C for 24 hours [9, 20]. The plant materials (leaves and thinly sliced cassava tuber) were dehydrated at 350C for 16 hours [21, 22, 23]. All dehydrated ingredients were ground using a 3kW Electric Grain Mill Grinder.

The predetermined ingredients were assessed for their nutritional compositions, based on theoretical proximate analysis.

Table 1. Theoretical proximate composition of the carbohydrate ingredients, compared to traditional aquafeed inputs.

| Proximate composition | Maize/ Corn | Bran

(wheat/corn/ rice) |

Cassava Flour | Brewers Spent Grain | Sweet Potato Leaf Meal |

| Moisture (%) | 0 | 10-15 | 61.8 | <15 | 9 |

| Crude Lipid (%) | 3.6 | 3-22 | 0.8 | 4-10 | 2.4 |

| Crude Protein (%) | 8-11 | 10-17 | 3.1 | 20-50 | 26-33 |

| Ash (%) | 1.4 | 8-17 | 2.7 | 12 | 1.8 |

| Crude fibre (%) | 2.3 | 6-14 | 1.5 | 30-50 | 4.7 |

| Digestible energy (Mj/kg) | 18.6 | 12- 16 | 29.8 | 7.2 | 34 |

Table 2. Theoretical proximate composition of the protein ingredients, compared to traditional aquafeed inputs.

| Proximate composition | Fish- Meal | Soybean Meal | BSFL Meal | Fish Offal Meal | Moringa Leaf Meal | Brewers Spent Grain | Sweet Potato Leaf Meal |

| Moisture (%) | 8 | 13 | 5.3 | 8-10 | 7 | <15 | 9 |

| Crude Lipid (%) | 9 | 5 | 20-35 | 13.5 | 7.09 | 4-10 | 2.4

|

| Crude Protein (%) | 71 | 46-48 | 32-60 | 54.5 | 23-30 | 20-50 | 26-33 |

| Ash (%) | 12 | 6 | 7.3 | 19.8 | 12 | 12 | 1.8 |

| Crude fibre (%) | – | 32 | 7.4 | 0.76 | <5.9 | 30-50 | 4.7 |

The Microsoft Excel ‘Trial and Error’ method was used to formulate the diet using the identified ingredients [24, 25] and to determine the specific quantities of each ingredient required to make batches of pellets (Table 3).

Table 3. The trial-and-error method.

| Ingredient | Protein % of ingredient | Fat % of ingredient | % Diet made up by ingredient | % Protein in fish diet | % Fat in fish diet | Quantity of ingredients (g) to make 1 kg of pellets |

| Fish Offal | 54 | 13.1 | 69 | 37.26 | 9.039 | 690 |

| Lobster | 29 | 2.2 | 5 | 1.45 | 0.11 | 50 |

| Moringa Leaves Dried | 30 | 4 | 1 | 0.3 | 0.04 | 10 |

| Cassava Leaves Dried | 17 | 5 | 1 | 0.17 | 0.05 | 10 |

| Brewers Grain | 23 | 6.4 | 1 | 0.23 | 0.064 | 10 |

| Cassava Flour | 3 | 0.8 | 20 | 0.6 | 0.16 | 200 |

| Soybean Oil | 0 | 100 | 1 | 0 | 1 | 10 |

| Black Soldier Fly Larvae | 32 | 20 | 2 | 0.64 | 0.4 | 20 |

| Total | 100 | 40.01 | 10.863 | 1000 |

The diet was formulated to ensure 40% protein and 10% lipids, which closely matches the commercial feed used for juvenile tilapia. The predetermined quantities of ingredients were combined to form a dough using warm water. The dough was then extruded through the ‘Techtongda Animal Pellet Feed Mill Grinder’ to form 3 mm diameter pellets and then baked in an oven at 930C for 20 minutes to obtain moisture contents of >10%, before being cooled and stored in a refrigerator at 50C.

Stability and Palatability Test

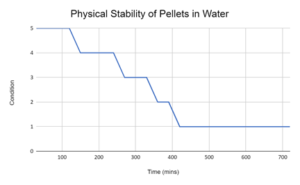

The stability of the homemade pellets was assessed to determine their suitability for use as an aquafeed. Complete pellets were placed in a 5-gallon aquarium containing freshwater maintained at 280C and observed for 12 hours. The physical structure of the pellets was ranked from 1-5 with 5 suggesting that the pellet maintained its shape and size and 1 being that it had disintegrated in the water. The results represented in Fig. 1 show that pellets started to lose their form after two hours.

Figure 1. Structural stability of pellets in water over time

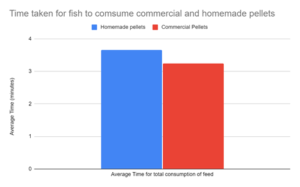

In order to determine palatability of the homemade pellets, fish were provided with pellets and observed. The amount of time taken for pellets to be consumed was recorded and is represented in Fig. 2.

Figure 2. Time taken for fish to consume

Feed Trial

Four 120-gallon tanks were designated in a recirculating aquaculture system at the Cape Eleuthera Institute in The Bahamas for this experiment. This experiment was designed with two control tanks being fed Cargill Triton 4010 Transition pellets and two tanks fed the homemade pellets. Each tank contained 8-10 fish between 80g-230g being fed 5% biomass daily, which was recalculated bi-weekly.

Water quality parameters were maintained at the following levels throughout the feed trial: ammonia: 0-0.25; pH: 6.8-7.0; temperature: 24-270C; dissolved oxygen saturation: 75-100%.

Data Collection

Fish were sampled weekly, and measurements of weight (g), total length (cm) were recorded. These measurements were used to calculate various growth metrics, such as specific growth rate (SGR), feed conversion rate (FCR) and condition factor (K). Health metrics such as relative ventricular mass (RVM) and hepatosomatic index (HSI) were also obtained from a selection of fish at the beginning of the experiment, and then at the end with all remaining fish.

Results and Discussion

Feed Trial Analysis

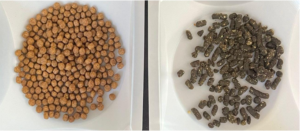

This section reports on the results of the evaluation of the performance of the home-made pellets compared to the commercial diets typically used in aquaculture production in the Bahamas. The pellets were produced via heat extrusion as sinking pellets that were similar in size to the commercial pellets.

Figure 3. Commercial pellets (left) and Homemade pellets (right)

The health and growth metrics mentioned in the methods section were calculated and compared using an analysis of variance test. This is represented on the table below.

Table 4. Results of Growth Trial conducted on juvenile tilapia where HM represents homemade feed diet and C represents Commercial feed diet.

| Diet | SGR | FCR | K | RVM | HSI |

| HM1 | 1.01 | 1.84 | 1.77 | 0.053 | 1.536 |

| HM2 | 1.49 | 1.75 | 1.84 | 0.057 | 1.829 |

| C1 | 1.57 | 1.74 | 1.85 | 0.078 | 2.351 |

| C2 | 1.09 | 2.34 | 1.63 | 0.0486 | 1.824 |

| p | 0.42 | 0.28 | 0.29 | 0.67 | 0.34 |

Specific Growth Rate (SGR)

The SGR indicates the rate at which the organisms are growing over a specific period. A higher SGR value suggests better growth performance. The SGR values for the trials range from 1.01 (HM1) to 1.57 (C1), with C1 showing the best growth performance. While the difference is not significant, it indicates that the homemade diet can be refined to improve growth performance.

Feed Conversion Ratio (FCR)

The FCR measures the efficiency of feed usage, defined as the amount of feed required to gain a certain amount of biomass. A lower FCR value indicates better feed efficiency. The FCR values range from 1.74 (C1) to 2.34 (C2). C1 shows the most efficient feed usage, while C2 is the least efficient. This suggests that the homemade feed was more easily digested and converted to biomass than commercial feed.

Condition Factor (K)

K is used to determine how well fish grow and how effectively they are utilizing feed. A higher K value generally indicates that the fish are in better condition, often linked to better growth, fat storage, and overall health. A low K value may suggest poor growth, inadequate feeding, or suboptimal environmental conditions. The K values in the table suggest that all fish in the different treatments have relatively similar condition factors. The values range from 1.98 (HM2) to 2.06 (C2), indicating that the fish across all treatments received adequate nutrition to maintain their physical condition and overall health.

Relative Ventricular Mass (RVM)

RVM values range from 0.0486 (C2) to 0.078 (C1). This implies that while the fish fed on homemade feed may have slightly lower heart mass compared to those on commercial feed, the difference is not enough to suggest poor cardiovascular health.

Hepatosomatic Index (HSI)

HSI represents the ratio of liver weight to total body weight, often used to assess nutritional status and overall health. HSI values ranged from 1.536 (HM1) to 2.351 (C1). This suggests that while fish on the commercial diet may have a slightly higher liver mass (which can be associated with nutrient processing and storage), the fish on homemade feed are still within a healthy range. Lower HSI could imply better liver efficiency in nutrient utilization or less fat accumulation in the liver.

Statistical Analysis

The p-values are all above 0.05, indicating that there is no statistically significant difference in the SGR, FCR, K, RVM, or HSI among the four trials. This suggests that based on the observed metrics, there is no significant difference in growth or health condition of the fish fed commercial feed and those fed homemade feed. Further, since all of these values fell within the typical range for juvenile tilapia, this suggests that the homemade feed is able to support growth and health in juvenile tilapia over a 6-week period similarly to the imported commercial feed.

Cost Analysis of Homemade Feed

The table below shows the breakdown of cost associated with formulating the homemade feed diets. The cost of commercial feed currently being utilized at the Cape Eleuthera Institute is imported from the United States and costs USD 2.43/kg.

Table 5. Breakdown of production costs of homemade tilapia feed.

| Ingredient | Unit cost | Total Cost | Processing (electricity) Cost | Labour | Pelletizing (electricity cost) | Total Production cost | Cost per kg |

| Fish offal | 4.13 | 30 | 1.95 | ||||

| Lobster discard | 4.13 | ||||||

| Moringa leaf meal | 1.46 | ||||||

| Cassava leaf meal | 1.46 | ||||||

| Brewers’ grain | $0.1 total | 0.1 | 0.02 | ||||

| Cassava flour | $10/kg | 8.8 | 0.00 | ||||

| Soybean oil | 0.01 | 0.4802 | 0.00 | ||||

| BSFL | 1.54 | ||||||

| Total | 9.3802 | 14.70 | 30 | 54.08 | 19.31 |

The homemade feed cost per kg ($19.31) is significantly higher (8 times) than the cost of imported commercial feed ($2.43/kg). The majority of the cost of making the feed can be attributed to labour ($30) and electricity ($14.70). Commercial feeds are typically mass-produced, which reduces per unit costs, whereas homemade feed production is less efficient, with high associated labor and processing costs. Another significant portion of the cost in the homemade feed comes from ingredients such as cassava flour ($8.80) and BSFL ($1.54), which are expensive on a per kg basis. Conversely, some ingredients like fish offal and brewers’ grain are relatively cheap, however the overall cost is driven up by other high-cost ingredients.

While the homemade feed provides control over ingredient selection and may offer nutritional or environmental benefits, the high production cost is not competitive with the lower price of commercially produced fish feed. This difference could make it difficult for farmers to justify homemade feed, especially when cost-effectiveness is crucial for profitability.

Measures can be taken to make the homemade feed more cost comparable.

-Reducing cost of inputs- revision of the formulation to include more of the cheaply available ingredients, and potentially reduce the total number of ingredients used would help reduce overall the cost of the feed.

-Reduce cost of processing- utilizing low energy or renewable energy options in processing (solar dehydration vs electric) would reduce the costs associated with preparing the ingredients for the diet. Scaling up production of the feed would also contribute towards reducing the cost to process each batch of feed since the labour and energy being used would be spread over a larger quantity of feed.

-Exploring alternative ingredients and processing methods (such as the use of fermentation of plant material) would help provide the essential nutrition for fish while reducing the cost associated with ingredients and processing.

Conclusion

This investigation into homemade feed formulation indicates that with some modification, it may be a reliable and suitable alternative to imported commercial feeds, supporting local sustainable aquaculture practices without significantly sacrificing performance. To explore the viability of these practices, a sequence of additional events will be investigated. To address accessibility and economics, a focus on shelf life and storage condition improvements provides potential to reach more stakeholders and increase scale of production in an effort to reduce costs. An examination of growth and health parameters on a full life cycle trial will introduce an expanded knowledge on comparative performance to the standardized commercial feed. A review of the ingredient combinations and an inquiry into additional substitution sources may generate a feed that outcompetes the nutrition value of the constructed feed from this study. By working towards the localization of feed production for aquaculture, the country stands to gain more autonomy over the sector and its holistic development. There are also the environmental and sustainable advantages for making feed locally and reducing the needs for carbon-fueled imports.

This research serves as a solid foundation upon which tilapia aquaculture farmers throughout the tropics with access to similar ingredients can develop novel feeds. The formulations can also be adapted to suit the nutritional requirements of other economically and culturally important aquaculture species.

References

- Garlock, T., Asche, F., Anderson, J., Bjørndal, T., Kumar, G., Lorenzen, K., Ropicki, A., Smith, M. D., & Tveterås, R. (2020). A global blue revolution: Aquaculture growth across regions, species, and countries. Reviews in Fisheries Science & Aquaculture, 28(1), 107–116. https://www.tandfonline.com/doi/abs/10.1080/23308249.2019.1678111

- Pradeepkiran, J. A. (2019). Aquaculture role in global food security with nutritional value: a review. Translational Animal Science, 3(2), 903-910. https://academic.oup.com/tas/article-abstract/3/2/903/5487790

- (2016). The State of Food and Agriculture: Climate chnage, agriculture and food security. In FAO. http://books.google.com/books?id=V1qrPwAACAAJ&dq=intitle:Livestock+in+the+balance&hl=&cd=15&source=gbs_api%5Cnpapers2://publication/uuid/F6B30CC3-5968-4026-8CAD-676C21F4EDBC

- Adewolu, M. A. (2008). Potentials of sweet potato (Ipomoea batatas) leaf meal as dietary ingredient for Tilapia zilli fingerlings. Pakistan Journal of Nutrition, 7(3), 444–449. https://www.doc-developpement-durable.org/file/Culture/Culture-plantes-alimentaires/FICHES_PLANTES/Patate-douce/Potentials%20of%20Sweet%20Potato%20Leaf%20Meal.pdf

- Jeffs, A., & Davis, M. (2003). An assessment of the aquaculture potential of the Caribbean spiny lobster, Panulirus argus. https://core.ac.uk/download/pdf/19540635.pdf

- Craig, S. R., Helfrich, L. A., Kuhn, D., & Schwarz, M. H. (2017). Understanding fish nutrition, feeds, and feeding. https://vtechworks.lib.vt.edu/bitstreams/24c04f50-8d2f-4b2d-9f8a-9ec3684537a1/download

- Premawansha, K. K. K., de Silva, M. K. S., Gunawickrama, K. S., & Swther, B. S. (2022). Nutritional Evaluation of Fish Feeds Formulated with Fish Discards or Shellfish Waste as Alternative Protein Sources. Fishery Technology, 59(1), 39-48.

- English, G., Wanger, G., & Colombo, S. M. (2021). A review of advancements in black soldier fly (Hermetia illucens) production for dietary inclusion in salmonid feeds. Journal of Agriculture and Food Research, 5, 100164. https://www.academia.edu/download/89839361/main.pdf

- Fernandes, H., Castro, C., Salgado, J. M., Filipe, D., Moyano, F., Ferreira, P., Oliva-Teles, A., Belo, I., & Peres, H. (2022). Application of fermented brewer’s spent grain extract in plant-based diets for European seabass juveniles. Aquaculture, 552, 738013. https://www.sciencedirect.com/science/article/pii/S0044848622001272

- Gokulakrishnan, M., Kumar, R., Ferosekhan, S., Siddaiah, G. M., Nanda, S., Pillai, B. R., & Swain, S. K. (2023). Bio-utilization of brewery waste (Brewer’s spent yeast) in global aquafeed production and its efficiency in replacing fishmeal: From a sustainability viewpoint. Aquaculture, 565, 739161. https://www.sciencedirect.com/science/article/pii/S0044848622012790

- San Martin, D., Orive, M., Iñarra, B., Castelo, J., Estévez, A., Nazzaro, J., Iloro, I., Elortza, F., & Zufia, J. (2020). Brewers’ spent yeast and grain protein hydrolysates as second-generation feedstuff for aquaculture feed. Waste and Biomass Valorization, 11, 5307–5320. https://link.springer.com/article/10.1007/s12649-020-01145-8

- Dada, A. A., Adeparusi, E. O., & Malomo, E. O. (2015). Dietary utilization of different portions of sweet cassava root (Manihot palmata) for the Nile tilapia Oreochromis niloticus (Linnaeus, 1758). Journal of Fisheries and Aquatic Science, 10(6), 569. https://search.proquest.com/openview/d582884d52a916ed3558822f40efe58a/1.pdf?pq-origsite=gscholar&cbl=276274

- Madalla, N. (2008). Novel feed ingredients for Nile tilapia (Oreochromis niloticus L.).

- Kasiga, T., & Lochmann, R. (2014). Nutrient Digestibility of Reduced‐Soybean‐Meal Diets Containing Moringa or Leucaena Leaf Meals for Nile tilapia, Oreochromis niloticus. Journal of the World Aquaculture Society, 45(2), 183-191. https://onlinelibrary.wiley.com/doi/abs/10.1111/jwas.12102

- Karina, S., Akbar, M., Supriatna, A., & Muchlisin, Z. A. (2015). Replacement of soybean meal with Moringa oleifera leaf meal in the formulated diets of tilapia (Oreochromis niloticus) fingerlings. Aquaculture, Aquarium, Conservation & Legislation, 8(5), 790-795. https://search.proquest.com/openview/fbaa0f3f3f77d329dc7543ebe45acc5e/1?pq-origsite=gscholar&cbl=2046424

- Farahiyah, I. J., Wong, H. K., Zainal, A. A. R., & Ahmad, A. (2015). Fish offal meal as an alternative protein source of fish meal for Tilapia, Oreochromis sp. Malaysian J. Anim. Sci, 18(2), 81–86. https://mjas.my/mjas-v2/rf/pages/journal/v18i2-8.Fara-fish_r3.pdf

- Kamau, E., Mutungi, C., Kinyuru, J., Imathiu, S., Tanga, C., Affognon, H., Ekesi, S., Nakimbugwe, D., & Fiaboe, K. K. M. (2018). Moisture adsorption properties and shelf-life estimation of dried and pulverised edible house cricket Acheta domesticus (L.) and black soldier fly larvae Hermetia illucens (L.). Food Research International, 106, 420–427. https://www.sciencedirect.com/science/article/pii/S0963996918300127

- Tippayadara, N., Dawood, M. A. O., Krutmuang, P., Hoseinifar, S. H., Doan, H. Van, & Paolucci, M. (2021). Replacement of fish meal by Black soldier fly (Hermetia illucens) larvae meal: Effects on growth, haematology, and skin mucus immunity of Nile Tilapia, Oreochromis niloticus. Animals, 11(1), 193. https://www.mdpi.com/2076-2615/11/1/193

- Muin, H., & Taufek, N. M. (2022). Evaluation of growth performance, feed efficiency and nutrient digestibility of red hybrid tilapia fed dietary inclusion of black soldier fly larvae (Hermetia illucens). Aquaculture and Fisheries. https://www.sciencedirect.com/science/article/pii/S2468550X22001642

- Thomas, M., Hersom, M., Thrift, T., & Yelich, J. (2010). Wet Brewers’ Grains for Beef Cattle: AN241/AN241, 5/2010. Edis, 2010(4). https://journals.flvc.org/edis/article/download/118590/116520

- Ali, M. A., Yusof, Y. A., Chin, N. L., & Ibrahim, M. N. (2017). Processing of Moringa leaves as natural source of nutrients by optimization of drying and grinding mechanism. Journal of Food Process Engineering, 40(6), e12583. https://onlinelibrary.wiley.com/doi/abs/10.1111/jfpe.12583

- Saint Sauveur, A. D., & Broin, M. (2010). Growing and processing moringa leaves. https://cgspace.cgiar.org/bitstream/10568/63651/1/moringawebEN.pdf

- Adéyèmi, A. D., Kayodé, A. P. P., Chabi, I. B., Odouaro, O. B. O., Nout, M. J., & Linnemann, A. R. (2020). Screening local feed ingredients of Benin, West Africa, for fish feed formulation. Aquaculture Reports, 17, 100386. https://www.sciencedirect.com/science/article/pii/S2352513420300739

- Catacutan, M. R. (2002). Formulation of aquafeeds. In Nutrition in Tropical Aquaculture: Essentials of fish nutrition, feeds, and feeding of tropical aquatic species(pp. 99-123). Aquaculture Department, Southeast Asian Fisheries Development Center. http://repository.seafdec.org/handle/10862/3318

- Onwurah, F. B. (2011). Excel feed formulation and feeding models. In 1st International Technology, Education and Environment Conference.

- Obuya, J. A., Sigana, D. A., Wang’ondu, V., Wambiji, N., Ong’anda, H. O., & Orembo, B. (2018). Length-weight relationship of selected teleost fishes from Kilifi County, Kenya. Western Indian Ocean Journal of Marine Science, 17(1), 125-135. https://www.ajol.info/index.php/wiojms/article/view/176417