Publication Information

ISSN: 2641-6816

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2018

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Quality Improvement of Thai Flat Rice Noodle Restructured with Starch Digested Enzyme and Resistant Rice Starch Type III

Jirapa Pongjanta1* and Chutima Lerdluksamee2

1Food Innovation Center, Agricultural Technology Research Institute, Rajamangala University of Technology Lanna, Thailand

2Faculty of Food and Agricultural, Pibulsongkram Rajabhat Universit, Thailand

Received Date: 19 April, 2019; Accepted Date: 29 April, 2019; Published Date: 06 May, 2019

*Corresponding Author: Jirapa Pongjanta, Food Innovation Center (Assist.Prof. Dr. RMUTL) P.O box 89 Phichai, Muang (Dist.), Lampang, 52000 Thailand. Email: jiratawan@gmail.com

Citation: Pongjanta J, Lerdluksamee C (2019) Quality Improvement of Thai Flat Rice Noodle Restructured With Starch Digested Enzyme and RRS III. Adv Nutri and Food Sci: ANAFS-129.

Abstract

Traditional flat rice noodle (gŭay-dtĭeow) is popular food in which was elastic texture and sweet taste of natural rice without food additive and chemical modified starch added. Now a day many traditional Gŭay-dtĭeowfactory got problem on elasticity texture, because of the physicochemical quality of broken rice change due to the climate change. Thus, the objective of this work is effort to improve the properties of flat rice noodle by using food grade enzyme and resistant rice starch type III (RSS III). Three food greed enzyme namely Pululanase (PLN), a-amylase (AML) and Glucoamylase (GML) were added during soaking broken rice grain for 16 hrs. The water from soaked rice were taken to analysis of total soluble solid, pH, and glucose content. The result found that the soaked rice water from 0.012% and 0.015% of AML was the highest of total soluble solid(TSS) (2.2 and 2.8oBrix) and glucose (10.27 and 15.34 g/100g glucose std.) and following by PLN and GML which was 0.9, 0.8, 0.5 and 0.4oBrix and 1.49,3.12, 1.22 and 2.55 g/100g glucose, respectively. The soaked rice samples were stone mill with water to produced rice flour slurry prior addition of cassava flour in the rice solution and mixed well before steaming, cutting and physicochemical analysis. Result revealed that the 0.012% glucoamylase treatment could improve the quality of the traditional Thai flat rice noodle which lowers on cooking lost value, higher in tension test and overall acceptance by 30 trained panelists than the other treatments. Thus, the GML enzyme treatment was selected for improvement of nutritional quality of the flat rice noodle by adding RRSIII with 0, 1 and 2% of total rice flour solution. Results revealed that the 1% of RRS III was the lowest on cooking loss, highest in Tensile-strength and total acceptance score by 30 panelists. In addition, nutrition value and in vitro starch digestibility revealed that an increase of RRS III content was a significant higher in resistant starch content and dietary fiber.

Keywords: Glucoamylase, Resistant starch, Rice noodle

Introduction

Recently, high fiber and low glycemic index foods are receiving increasing and interesting in the field of medical and nutrition. Because they have several health benefits such as help to maintain blood glucose level in diabetic individuals. Traditional flat rice noodle (gŭay-dtĭeow or flat rice noodles) is popular food in Thailand which was served with the addition of meatballs, fish ball, pork-chop, seafood, fish or soy sauce as well as vegetable such as bean-sprout and cabbage. The good characteristic of natural flat rice noodle is sweet taste, high rate of rice aroma and texture elasticity. Traditional production of flat rice noodle are produced by machines with 4 major steps are selecting raw high amylose broken rice, washing, soaking, grinding, steaming, sheeting and cutting. The important processing step of flat rice noodle is broken rice soaking. The purpose of soaking is to allow water to penetrate into the rice kernel, which results in a high moisture content and less rigid structure with has about 45% moisture content, is suitable for wet grinding. Wet grinding produces to rice slurry with a smooth consistency. Cooking and textural qualities are two main attributes of flat rice noodle [1].The qualities and shelf-life of flat rice noodle are affected by raw materials, storage condition and manufacturing process. Generally, flat rice noodle have a high moisture content (60-62%) and water activity between 0.90-0.92 thus its produced short shelf life within 2-3 days [2].

Currently, Gŭay-dtĭeow factory had problem on elasticity texture due to stalling after 3 days storage. These problem caused by the quality of broken rice that changed by genetic and global warning. Flat noodle staling was attributed by both of amylose and amylopectin content in broken rice. The amylose re-association is related to the short-term retro gradation during the initial few hours, while amylopectin re-crystallization is associated with product firming in the longer term. Recently, many researchers presented that enzymatic digested starch had been implicated as retarding staling of flat rice noodle and other noodle [3]. Traditionally, flat rice noodles are lack of dietary fiber content. According to the current health problem among children and teenagers is obesity that cause by taken high fat and carbohydrate which was lack of dietary fiber. Dietary fiber has water binding and alteration of viscosity functions and healthy benefit such as cholesterol and fat binding. Dietary fibers promote beneficial physiological-effects including, laxation, and/or blood-cholesterol attenuation and/or blood-glucose attenuation. Serum cholesterol can be reduced because it has capacity to bind bile acid [4]. It also improves constipation management and B12 bioavailability in the elderly with multiple chronic diseases [5]. Thus, the main objective of this research was to improve the physicochemical and nutritional quality of the traditional flat rice noodle with starch digested enzymes and RRS III. The 5 days storage of the developed flat rice noodle samples were analysis on tension test, color value, cooking lost and sensory evaluation.

Methodology

Amylose broken rice (ABR), cassava flour (CF) was bought from local market in Lampag Thailand. While, the food grade enzyme PLN from B. subtilis (30,000 BPU/g), AML from B. subtilis (EC 3.2.1.1; 3,000 IU/mL) and GML A. niger ( EC 3.2.1.3; 200,000 U/mL) were bought from iKnownZyme. Analysis enzymes like, resistant starch assay kit (Megazyme) was obtained from Megasyme International Ireland Ltd., Ireland. Pepsin (EC 3.4.23.1; 2,980 unit/mg), α- amylase (E.C. 3.2.1.1; Type VI-B from hog pancreas; 20.4 unit/mg) and AMG (A-3042; 69.65 unit/mg, from Aspergillus niger),Glucose using Glucosidase assay kit (GAGO-20) were purchased from Sigma Chemical Company, USA. RRS III were prepared following the method described by Pongjanta et al., [3]

Chemical Composition of Raw Materials

ABR, CF and RRS III were determined on moisture content, amylose content and resistant starch content following methods in AOAC [9], Hoover [13].

Enzyme Activity Assay

The activity of the 3 food grade starch digested enzymes (PLN, AML and GML) was tested on hydrolysis rate of raw ABR. The three level (0, 0.012 and 0.015% of raw ABR) of each enzyme were added into the test tube that contained of 35 g raw ABR and the 45g of tab water was added and mixed well prior resting at room temperature for 16 hrs. Each of the soaked water from the tested tubes were taken for analysis on total soluble solid (TSS), glucose content and pH by using hand refractometer, glucose assay kit (GAGO-20) and pH-meter, respectively. The chemical analysis was done with 3 replications.

Flat rice noodle preparation

The 3 kg of ABR were triplicated washing before added tap water 4 kg and mixed well. The PLN, AML and GML enzyme were added at 0, 0.012 and 0.015% of raw ABR and mixed well before soaked at room temperature for 16 hrs. The water from soaked rice were taken for analysis of total soluble solid, pH, and glucose content.

The soaked rice samples were stone mill with water to produced rice flour slurry prior addition of cassava flour in the rice solution and mixed well before steaming, cutting and physicochemical analysis. Result revealed that the 0.012% GML treatment could improve the quality of the traditional Thai flat rice noodle which lowers on cooking lost value, higher in tension test and overall acceptance by 30 trained panelists than the other treatments. Thus, GML treatment was selected for improvement of nutritional quality of the flat rice noodle by adding RRS III with 0, 1 and 2% of total rice flour solution. Results revealed that the 1% of RRST3 was the lowest on cooking loss, highest in tensile strength and total acceptance score by 30 panelists. In addition, nutrition value and in vitro starch digestibility revealed that an increase of RRS III content was a significant higher in resistant starch content and dietary fiber. The two level of the each enzyme (0, 0.012 and 0.015 % of rice grain) were added during soaking of ABR (35%) in tap water (45%) for 16 hrs. The enzyme soaked rice water were drained and taken for analysis on total soluble solid, pH, and glucose content. The enzyme hydrolysis of ABR was stone milled for 3 times repeated with 5% of tap water added. The 1% of the rice flour solution was taken and dewater by centrifuged prior drying at 60oC for 4 hours to below 8% moisture content prior package in polyethylene bag for physicochemical analysis on:

Morphologic Image

The wet milled enzyme hydrolysis ABR flour and the developed flat rice noodle morphologic structure were examined by a scanning electron microscopy (SEM): SEM S-4300; Hitachi, Tokyo Japan). Dehydrated samples were attached to a copper stub using double-size adhesive tape were than attached with gold using vacuum evaporator. A magnification of 1000x and 4,500x were applied for observing micro granule structure.

X-ray Diffraction Patterns

The wet milled enzyme digested ABR flour were measured with copper K2 radiation (l =0.154 nm) using a diffractometer (JEOL, JDX-3530, Japan), operated at 300 mA and 30 kV, 2q range from 0 to 50.0o with a step size 0.05o and a count time of 2s. The data was analyzed with a MDI Jade 6.5 (Japan) program. The crystallinities of the rice flour samples were calculated as the proportion of crystalline area to total area at angles between 12 to 47 o 2q [8].

Pasting Properties

Of the partially hydrolysis rice flour samples were evaluated using a RVA (Model RVA-4, Newport Scientific Pty Ltd, Australia), following the AACC method 61-02.01. Thermocline software helped to calculate pasting temperature (PT), peak viscosity (PV), trough viscosity (TV), final viscosity (FV), setback (SB=FV-PV), and breakdown (BD=PV-TV).

Flat Rice Noodle Production

The remained of ABR flour solution was continued to produced flat rice noodle by adding 5% of cassava flour and then mixed well before steaming to formed sheeted then cooling and cutting to rectangle 1 mm thick ,4-6 mm wide and 200 mm long before packing in polyethylene bag and storage at room temperature for 5days. The noodle samples were taken for physicochemical analysis and sensory evaluation every day with 3 replications. The best qualities of flat rice noodle after 5 days storage was selected for dietary fiber improvement by added of RRS III during rice flour milling at 0, 1 and 2% of total flour solution and process to flat rice noodle as above steps. The physicochemical analysis, in vitro starch digestibility and sensory acceptance of the high dietary fiber flat rice noodle were investigated as following method.

Determination of Flat Rice Noodles

Physicochemical quality of 1 to 5 days storage of noodle samples were analysis on cooking lose, tensile strength, noodle color, microbiology, sensory evaluation and as following method.

Cooking Loses

The solids lose during cooking of flat rice noodle was measured according to the AACC methods 66–50 [5]. Cooking 20 g of flat noodles in 300 mL distilled water for 5 minutes. The noodles were removed and remained water was dried in an oven at 105°C for 24 hrs. The dried residue was weighed and calculated as: % cooking loses is remained solid divide by weight of raw noodle and then multiply by 100.

Colorimetric Analyses: The color of flat rice noodle were carried out by CIELAB parameters L*, a* and b* using Hunter Lab D65-10 Reflectance Colorimeter.

Testing Tensile Strength

The strand of flat rice noodle was held in tensile grip by the texture analyzer. The flat rice noodles were placed one end into the lower arm of grip and the other end to upper arm. The upper arm was set to travel apart from the lower arm at the test speed of 1.0 mm/s with a rupture distance of 40 mm. The maximum force (g) required to break the cooked rice noodle strand gave an indication of sample resistance to the breakdown and the distance (mm) to break indicated its extensibility. The measurements were repeated 10 times for each sample.

Sensory Evaluation

The sensory properties of final developed flat rice noodle products are evaluated by 30 trained sensory panels. They trained panelists were evaluation each of the flat rice noodles according to 9 point hedonic scaling test [14]. Cooked noodle was rating on appearance, aroma, taste, texture and overall acceptability. Sensory data were collected and analysis.

Microbiology Analysis

The good quality of flat rice noodle sample was determined on total bacteria counts using the pour plate method following FDA-1995 [12]. Collected data were expressed as colony forming unit (CFU) per gram sample.

Chemical Composition

The good physical and sensory quality of the developed flat rice noodle was selected for analysis on moisture, protein, fat, ash dietary fiber, carbohydrate and resistant starch content following methods in AOAC [9].

Statistical Analysis

All analyses were carried out in triplicates and reported as means and standard deviation. Data were analyzed by one way ANOVA and statistical significance with Duncan’s multiple range test (P < 0.05).

Results and Discussion ±0.04a ±0.35 b ±0.20 b ±0.32 b ±0.12 c ±0.32b ±1.40 c ±0.32 c ±0.12 a ±0.46c ±1.40 a Table 1. Chemical composition of raw materials for flat rice noodle production. Enzyme Activity Assay in Laboratory (oBrix) a, b...significantly different (p<0.05)

Chemical Composition of Raw Materials

Moisture, amylose, protein and resistant starch content of ABR, CF and RRS III show in (Table 1). Results revealed that ABR and cassava flour were higher in moisture content and protein content than RRS III. In addition, RRS III was the highest in amylose and resistant starch content. This due to the raw materials used and enzymatically modified of high amylose rice starch to produced RRS III with high in resistant starch [3].

Raw materials

Chemical composition (%)*

Moisture content

Amylose content

Protein content

Resistant starch

ABR

14.0

24.81

6.06 ±0.45a

2.60

CF

11.55

20.10

2.80

1.70

RRS III

7.45

26.10

1.23

25.20

The results are expressed on average± ESMa, b...significantly different (p<0.05)

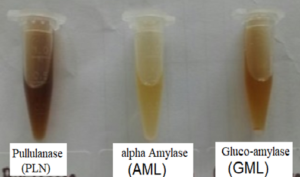

An appearance of the 3 starch digested enzymes, soaked ABR and chemical compassion of the soaked water reveled in (Figure 1 and Table 2). Result found that the AML enzyme had the highest raw starch degradation which was contained of TSS between2.2 to 2.8 o Brix and 10.27 to 15.34 % glucose content in the soaked water. In additional, the soaked water from PLN enzyme was the second on raw starch hydrolysis (0.8 to 0.9oBrix and 1.22 to 3.12 % glucose content) and the lowest of TSS and glucose content was GML enzyme (0.4 to 0.5oBrix and 1.22 to 2.55%).Furthermore, pH content was higher in control soaked water (pH 6) than the soaked water with the 3 enzymes that had pH within 5.14 to 5.22.Thus, the less amount of the 3 enzymes (0.012% of ABR) were selected for hydrolysis of ABR during soaking of ABR with water for 16 hrs. before milling and produced to flat rice noodle samples in factory scale. (A)

(A)

(B)

Figure 1 A, B: appearance of the 3 starch digested enzymes (A) and experimental on soaked of ABR (B)

Treatments*

TSS

Glucose content (%)

pH

Control

0.4c

0f

6.00ns

0.012% of PLN

0.8b

1.49e

5.22

0.012% of AML

2.2a

10.27b

5.30

0.012% of GML

0.4c

1.22e

5.18

0.015% of PLN

0.9 b

3.22c

5.16

0.015% of AML

2.8a

15.34a

5.18

0.015% of GML

0.5c

2.55d

5.14

The results are expressed on average ± ESM

Chemical Composition of Soaked Water and Wet Mill Rice Flour

Chemical composition of tab water, soaked water from noodle factory production scale that was taken after the 3 enzymes hydrolyzed of ABR grain for 16 hours show in Table 3. Results revealed that the soaked water from AML enzyme hydrolyzed ABR grain had the lowest in pH content (4.19) and following by GML and PLN enzyme, respectively. While, the tab water and control soaked water had pH between 7.54 and 7.87. In addition, TSS and glucose content in the soaked water from AML enzyme had the highest in TSS (2.50 o Brix) and glucose content (13.73%) and following by PLN and AMG enzyme, respectively. Furthermore, analysis result on amylose content revealed the control wet milled rice flour had the highest (26.80%) and followed by the ABR flour produced from GML, PLN and AML enzyme hydrolyzed of ABR grain, respectively. These due to the enzyme hydrolyzed the α-1,4 amylose linkages of ABR.

| Soaked water | pH | TSS

(ºBrix) |

Glucose Content (%) | Amylose

Content (%) |

| Tap water | 7.54 a | 0.00 d | 0.00 e | 0.00e |

| Control | 7.87a | 0.50 c | 1.50 d | 26.80 a |

| PLN | 6.09 b | 1.50 b | 1.90 b | 25.40 c |

| AML | 4.19 d | 2.50 a | 13.73 a | 24.50 d |

| GML | 5.01 c | 1.10 b | 1.46 c | 26.10 b |

| The results are expressed on average ± ESM a, b...significantly different (p<0.05). | ||||

Physiochemical Properties of Enzymatically Hydrolyzed ABR Flour

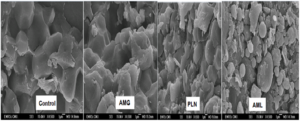

The morphological image, X-ray diffraction (XRD) pattern and viscosity behaviors of enzymatically hydrolyzed of ABR flour from factory production is shown in (Figure 2). The morphological granules of hydrolyzed ABR flour were polygonal shapes with diameters between 3-5 mm. The surface of the control starch granules was smoother than the enzyme hydrolyzed starch that shown surface erosion and slightly damaged. In addition, after enzymatic hydrolysis, ABR starches showed granules degraded mainly on their external surface and possibly internal surfaces and degrade the external part by exo-corrosion. In the surface of native starch granules, no pores or pits were observed. When ABR starches were hydrolyzed, the granule morphology was different to the native starch, granule degradation after AML hydrolyzed more than PLN and AMG enzyme. The XRD diffractograms of native and partially hydrolyzed ABR flour by α- amylase, PLN and AMG enzyme are shown in Fig.2, peaks were observed at 14°, 18° and 23° the most of rice flour presented an A-type diffraction pattern. The peak intensity and the crystallinity degree of enzymatic hydrolyzed ABR flour decreased slightly, the results of XRD indicated that amorphous structure was hydrolyzed faster than crystalline structure compared to control starch. X-ray diffraction pattern of the wet mill enzyme hydrolyzed was classified as an A-type pattern which was 45-58% of crystallinity degree. Results show that the AML hydrolyzed ABR susceptible to AML than are the AMG and PLN that was the lowest in crystallinity degree. Pasting behaviors of native and partially hydrolyzed ABR flour with AML, PLN and AMG enzyme are shown in (Figure 2). Results revealed that the control flour was the highest in peak viscosity and setback value, which was follow by partially hydrolyzed ABR flour with AMG, PLN and AML, respectively.

Figure 2 A, B, C: Morphological image (A), X-ray diffraction pattern (B) and Viscosity behaviors (C) of native and hydrolyzed ABR flour with 3 enzymes hydrolysis.

Physical Qualities of Flat Rice Noodles

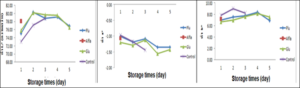

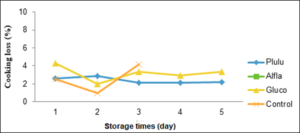

Appearance, color value, cooking lose, tensile strength of sheeted and cut flat rice noodle that produced from native and partially hydrolyzed ABR flour with AML, PLN and AMG enzyme and storage at room temperature for 5 day shown in (Figure 3). Results revealed that both of the first day storage of the 4 flat rice noodle samples was clearly white, smooth and elastic texture. However, the control flat rice noodle and AML hydrolysis were the highest in cooking lost and after 3 day storage. In addition, the noodle samples from PLN and GML hydrolysis of ABR were higher in tensile strength and lower in cooking lost than control and AML hydrolysis after 5 days storage at room temperature. Thus, AMG hydrolysis of ABR was selected for nutrition improvement of flat rice noodle with RRS III supplemented.

(A)

(B)

(C)

(D)

Figure 3 A, B, C, D: Appearance (A), color value (B), tensile strength(C) and cooking lost (D) of flat rice noodle that produced from hydrolyzed of ABR with AML, PLN and GML enzymes.

| Sensory attributed | Treatments | |||||

| Control | AML | PLN | AMG | |||

| Appearance | 7.10±0.19 | 7.70±0.74 | 7.40±0.14 | 7.80±0.64 | ||

| Color ns | 6.60±0.26c | 7.70±0.45a | 7.10±0.42b | 7.60±0.44ab | ||

| Rice aroma* | 6.30±0.41c | 7.86±0.33b | 7.80±0.73b | 8.06±0.53a | ||

| Flavor ns | 6.70±0.12 | 7.80±0.65b | 7.70±0.67b | 8.10±0.63a | ||

| Texture* | 6.00±0.51c | 7.10±0.54b | 7.50±0.52ab | 7.80±0.62a | ||

| Acceptance* | 6.40±0.17c | 7.10±0.42b | 7.70±0.43b | 8.40±0.43a | ||

| The results are expressed on average ± ESMa, b...significantly different (p<0.05) | ||||||

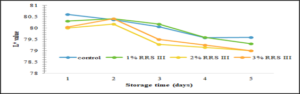

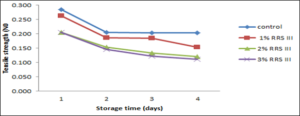

Physical and Sensory Qualities of Flat Rice Noodles with Enzyme Hydrolysis and RRS III Added

Physical Qualities

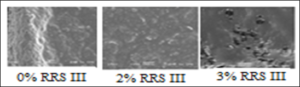

Appearance, L color value, tensile strength and micro structure of 5 days storage of cut flat rice noodle produced from AMG hydrolyzed ABR and supplemented of RRS III at 0, 1, 2 and 3% of total RRS III at 0, 1, 2 and 3% of total rice flour slurry show in Figure 4. Results revealed that an appearance of control and 1% of RRS III added in flat rice noodle were smoother texture and higher L* color value than the 2% and 3% of RRS III added. Furthermore, tensile strength value was higher in control than the RRS III added treatments during 5 days storage. The control sample was the highest in tensile strength value after 4 days storage. This might be due to the level of RRS III optimum for absorbed water. In addition, the morphological image of surface and cross section of the developed flat rice noodle shown that was smoother than the other treatments. The rough surface increased with high level of RRS III supplemented this due to the higher of crystallinity degree of RRS III than the native ABR (Figure 5)

(A)

(B)

(C)

(D)

Figure 4: Appearance, L color value, tensile strength and micro structure of 5 days storage of cut flat rice noodle produced from AMG hydrolyzed ABR and supplemented of RRS III at 0, 1, 2 and 3% of total rice flour slurry

Figure 5: Morphological image of surface section of 5 days storage of flat rice noodle from AMG hydrolyzed ABR and supplemented of RRS III at 0, 1, 2 and 3% of total rice flour slurry

Figure 5: Morphological image of surface section of 5 days storage of flat rice noodle from AMG hydrolyzed ABR and supplemented of RRS III at 0, 1, 2 and 3% of total rice flour slurry

Sensory Attributes of Developed Flat Rice Noodles

The 4 treatments cooked flat rice noodles with clear soup was served to 30 panelists to taste the noodle sample and evaluated on appearance, aroma, taste, texture and overall acceptability. The sensory evaluation results The 1% RRS III added in noodle formulae was the highest score of appearance, color, rice aroma, flavor, elastic texture and total acceptance by 30 trained panelists after 5 days storage at room temperature in (Table 5). From the overall result on physical and sensory qualities, the 1% RRS III added in noodle formulae was selected for total plate count and nutritive value analysis.

| Sensory attributed | % Resistant rice starch | |||

| 0 | 1 | 2 | 3 | |

| Appearance ns | 7.10±0.99 | 7.80±0.84 | 7.60±0.84 | 7.60±1.07 |

| Color ns | 7.60±0.96 | 7.70±0.48 | 7.70±0.48 | 7.60±0.51 |

| Rice aroma* | 6.40±0.96c | 8.60±0.73a | 7.10±0.73b | 6.90±0.99c |

| Flavor ns | 7.70±0.82 | 8.10±0.67 | 7.70±0.67 | 7.10±0.73 |

| Texture* | 7.00±0.81a | 7.80±0.52ab | 7.50±0.52ab | 6.90±0.73b |

| T acceptance* | 7.60±0.87a | 7.80±0.48a | 7.70±0.48a | 7.00±0.47b |

| The results are expressed on average ± ESM a, b...significantly different (p<0.05) | ||||

Nutritive Value and Total Bacteria Counts

Result on nutritive value and total bacteria counts of the original and developed flat rice noodle illustrated in (Table 6). Analysis results found the developed flat rice noodle had higher dietary fiber and resistant starch content than the original noodle. While, moisture, protein, fat, ash, carbohydrate content and total energy were higher in original noodle than the developed flat rice noodle. In addition, both of original and developed flat rice noodles had total bacteria count less than 30 colony forming unit per gram sample.

| Nutritive value

(% wet basic ) |

Noodle samples | |

| Control | Developed | |

| Moisture | 58.24±3.29a | 55.01±2.48b |

| Protein ns | 2.60±0.21 | 2.56±0.10 |

| Fat ns | 2.68±0.13 | 2.32±0.24 |

| Ash ns | 0.14±0.09 | 0.19±0.02 |

| Dietary fiber | 0.24±0.02b | 1.48±0.64a |

| Carbohydrate | 45.65±2.43a | 40.52±2.46b |

| Resistant starch | 2.42±0.14b | 5.82±1.28a |

| Total energy (kcal) | 216.30±5.12a | 191.20±4.26b |

| TBC (CFU/g sample | <30 | <30 |

| The results are expressed on average ± ESM a, b...significantly different (p<0.05) | ||

Conclusion

An improvement of tensile strength and dietary fiber content of flat rice noodle could be produced by GML enzyme hydrolysis of ABR and 1% supplemented of RRS III. The developed noodle was lowest on cooking loss, highest in tensile strength and total acceptance score by 30 panelists. In addition, the developed flat rice noodle was a significant higher in dietary fiber and resistant starch than the control flat rice noodle. From the results, it was concluded that both GML enzyme and RRS III can be explored effectively for preparing 'kway teow' or flat rice noodles, which is envisaged to hold high promise in local market.

Acknowledgement

The authors are grateful for the financial supports provided by Northern Science Park via Pibulsongkram Rajabhat University, Thailand and Rajamangala University of Technology Lanna. We also thanks to the Food Innovation Center Agricultural Technology Research Institute and Department of Agro-Industry Faculty of Science and Technology Rajamangala University of Technology Lanna for laboratory supported.

Reference

- Hormdok R, Noomhor A (2007) Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT 40: 1723-1731.

- Fu BX (2008) Asian noodles: History, classification, raw materials, and processing. Food Research International 41: 888-902.

- Pongjanta J, Utaipatanacheep A. Naivikul O, Piyachomkwan K (2008) Debranching enzyme concentration effected on physicochemical properties and glycemic index of resistant starch type III from high amylose rice starch. Carbohydrate Polymer 78: 5-9.

- Drizikova B, Dongowski G, Gebhardt E, Habel A (2005) The composition of dietary fibre rich extrudates from oat affects bile acid binding and fermentation in vitro. Food Chemistry. 90: 181-192.

- Sturtzel B, Dietrich A, Wagner KH, Gisinger C, Elmadfa I (2010) The status of vitaminsB6, B12, folate, and of homocysteine in geriatric home residents receiving laxatives ordietary The Journal of Nutrition Health and Aging. 4: 219-223.

- Jirapa Pongjanta Ni-orn Chomsri and Sawit Mechou .(2016) Correlation of pasting behaviors with total phenolic compounds and starch digestibility of indigenous rice grown in upper northern Thailand. Functional Foods in Health and Disease 6: 133-

- Tunsuda Parinya, Ubonrat Phomphang, Napaporn Deesnam and Jirapa Pongjanta (2018) Physicochemical properties of low glycemic index-high fiber rice flour from storage rice grain and application in chocolate chip cookies as substitute for wheat flour. CurrentApplied Science and Technology Vol. 18 No.10p.

- AACC (1999) Approved Methods of Analysis: Determination of the Pasting Properties of Rice with the Rapid Visco Analyser, Method 61-0201, 11th Ed.; AACC International: St. Paul, MN.

- Association of official analytical chemists (17th ed.). Washington, DC: Association of Official Analytical Chemists.

- Thai Industrial Standard (2005) Instant Rice noodle. TIS 832-2005.

- Cheetham NWH, Tao L (1998) Variation in crystalline type with amylose content inmaize starch granules: An X-ray powder diffraction Carbohydrate Polymers 36: 277-284.

- FDA (1995) Aplin & Barrett Ltd. Filing of petition for affirmation of GRAS status. Food and Drug Admin., Fed. Reg 60: 64167.

- Hoover R, Ratnayake WS (2001) Determination of Total Amylose Content of Starch: Current Protocols in Food Analytical Chemistry; John Wiley & Sons, Inc.: West Sussex, UK.

- Shogren RL, Hareland GA, Wu YV (2006) Sensory evaluation and composition of spaghettifortified with soy flour. J Food Sci 71:1750-3841.