Publication Information

ISSN 2691-8803

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2019

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Optimizing Fermentation Process and Sensory Acceptability of Traditional Banana Beer (Urwagwa) Using a Bioprocess Method

Thierry Uzabakiriho1, 2*, Uzodinma Eunice Uche Osinachi2

1Musanze Polytechnic, Department of Agricultural Engineering, Rwanda

2Faculty of Agriculture, Department of Food Science and Technology, University of Nigeria-Nsukka, Nigeria

Received Date: December 18, 2023; Accepted Date: February 25, 2024; Published Date: March 29, 2024;

*Corresponding author: Thierry Uzabakiriho, Musanze Polytechnic, Department of Agricultural Engineering, Rwanda. Email: uzthierry@gmail.com

Citation: Uzabakiriho T, Osinachi UEU (2024) Optimizing Fermentation Process and Sensory Acceptability of Traditional Banana Beer (Urwagwa) Using a Bioprocess Method. Adv Agri Horti and Ento: AAHE-189

DOI: 10.37722/AAHAE.2024103

Abstract

This research study was conducted to optimize the fermentation process and sensory acceptability of traditional banana beer using Mixture design. Banana beer samples were produced from blends of banana juice, malted or non-malted sorghum, water, and hops. Saccharomyces Cerevisiae was used to ferment banana beers. Traditional banana beers were coded (S1, S2, S3) while improved banana beers (S4, S5,S6,S7,S8,S9,S10,S11, and S12) were produced by fermenting the mixture of banana juice under room temperature and pressure. The experimental design was based on Mixture I-optimal design using Design Expert software version 11.0. Experimental constraints were: 0.5≤A ≤0.9; 0.05≤ B ≤0.37; 0≤ C ≤0.05; 0≤ D ≤0.30, A, B, C and D represented banana juice’s brix, sorghum flour/malt, hops and water respectively. Produced samples were subjected to alcohol content, pH, methanol, Total Soluble Solid, Titratable Acidity (TA), Standard Reference Method (SRM) and sensory analyses. The alcohol content ranged from 3.75±1.06 - 6.12±0.70 % and the highest was obtained at the optimum pH of 4.15±0.07. The pH in all samples ranged from 3.53±0.14 - 4.78±0.05. Methanol content ranged from0.01±0.00 % to 0.76±0.02 %. Total Soluble Solid (TSS), TA, and SRM results were 2.00±0.00 - 24.00±2.82oBrix, 0.13±0.02 - 0.29±0.00%, and 6.08±0.24 - 12.14±0.52 respectively. Synergistically roasting, malting and mashing of sorghum significantly (p<0.05) helped to get the desired sensory characteristics of banana beers. Thus, the overall acceptability scores of traditional and improved banana beers ranged from 4.60±1.39 - 5.05±1.14 and 5.35±2.25 - 7.00±1.29 respectively.

Keywords: Fermentation, Banana beer, Malting, Saccharomyces Cerevisiae

Introduction

Banana beer is a weak alcoholic beverage that is popular throughout Africa. It is made by fermenting banana juice with cereal flour, often sorghum flour. This kind of beer is sweet and slightly hazy with a shelf life that may reach up to two weeks under correct storage conditions (Kubo and Kilasara, 2016). The processing method and ratio of ingredients used vary widely from country to country and with personal taste. In Kenya, banana beer made from sorghum or millet flour is known as “urwaga”. In Uganda, banana beer is called “lubisi” (Kubo and Kilasara, 2016). Rwandan banana beer is called “urwagwa”, and it is the most popular traditional alcoholic beverage produced from banana juice with malted or non-malted sorghum. Banana beer is produced to the effort to reduce wine and beer importation to favor local producers in East African Community (E.A.C.).

Banana is considered as climacteric fruit, and it is densely cultivated in E.A.C. Rwanda is among the ten largest banana producing countries in Africa, providing more than 3 million tons of bananas per year (Kumar et al., 2018). Uganda is the largest producer of banana in East African Countries and exports about 5 million tons per year (FAO, 2020). Nevertheless, the produce has short shelf life and the needy to preserve and transform it into other shelf stable products could bring much benefits to farmers who practice its cultivation. The effort to add value to this produce is backed by the fact that bananas are readily available, seasonal, and highly perishable. Banana beer improvement is crucial to the wellbeing of rural farmers and middle-income families. The consumption data of banana beer throughout East African countries are still a matter of concern. However, modernization and empowering short and medium enterprises (SMEs) by Rwanda Standards Board (RSB) in “Made in Rwanda” policy is changing some of the poor perceptions and mindset of the citizens.

Materials and Methods

Source of raw materials

Starting materials used for banana beers were purchased overseas and locally in Nigeria. Pectinase and hops (10% flavonoids) were bought from 3109 AA Schiedam Netherland. Brewer’s yeast was purchased from ‘Now foods Ltd’ in Nigeria (through: www.jumia.com.ng). Other raw materials were purchased from Ogige market (Nsukka Local Government Area-Enugu, Nigeria), as follows:

Bananas (Red Daca and Musa Cavendish)

Sorghum (Sorghum bicolor)

Distilled water

Hops (10% flavonoids)

Yeast (Saccharomyces Cerevisiae)

Preparation of raw materials

Banana juice preparation

Ripe banana bunches were bought from Ogige market in Nsukka Local government, Enugu State (Nigeria). Bananas were peeled, cut and mashed in Food Processing laboratory of Food Science and Technology department, University of Nigeria, Nsukka.

Indeed, banana juices were produced with pectinase solutions were used to treat banana puree and extract the banana juice. Firstly, ripen bananas were spilled and put in a blender (SSJ-999B, SUPPER SONNYJAPAN). In addition, the stage involved blending 400 grams of banana pulp with 100 ml of water to ease the blending process. Banana juice was obtained by mixing the blend with 10% w/v of pectinase solution. The mixture was blended until desired consistency was achieved. Therefore, banana juices were pasteurized using high temperature short time pasteurization (HTST) of 95oC for 5 seconds in order to avoid contamination of foreign yeasts and other microbial competitors.

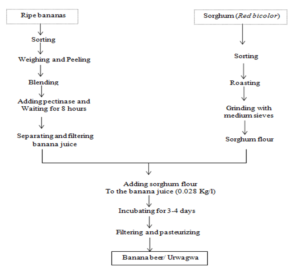

Traditional banana beers production

Traditional banana beers were produced using roasted sorghum, banana juice with no hops and dilution (Figure1). However, both malted and non-malted (roasted) sorghum flours were prepared by grinding sorghum malt and roasted sorghum with an electric grinder (SSJ-999B, SUPPER SONNYJAPAN). The mixture constraints and design expert data are shown in Table 1 and 2 below. Finally, yeast (1g/l) and non-malted sorghum flours were added to the juice (0.028 Kg/l). All the banana beers were fermented under a room temperature of 28oC, and normal pressure of 1 atmosphere.

Figure 1: Flow-chart for production of traditional banana beer

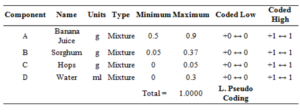

Table 1: Mixture constraints for banana beer production

Table 2: Design expert’s experimental data for traditional and improved banana beers production

Run

A. Banana juice (g)

B. Sorghum (g)

C. Hops (g)

D. Water (ml)

1

0.7

0.3

0

0

2

0.84

0.16

0

0

3

0.9

0.1

0

0

4

0.63

0.22

0.05

0.10

5

0.5

0.2

0.05

0.25

6

0.75

0.22

0.03

0

7

0.6

0.4

0

0

8

0.7

0.1

0.05

0.15

9

0.6

0.2

0.02

0.18

10

0.5

0.37

0.03

0.10

11

0.55

0.1

0.05

0.30

12

0.82

0.1

0.03

0.05

Improved banana beer production

Banana beers were produced using the bioprocess method. In this method, banana beers were produced by combining pasteurized banana juice with the wort from malted sorghum flour. Pasteurization of banana juice was carried out at 95oC for 5 seconds by using High Temperature short time. Moreover, roasting of malted sorghum was conducted to ease the kilning process at 150oC and adjust banana beer’s appearance (see Figure 2). Moreover, hops were added at different ratios in order to increase the aroma and taste of improved banana beer (Figure 2).

Figure 2: Flow-chart for the production of improved banana beer

Physicochemical parameters measured for banana beers produced

The equipment used were properly calibrated in Food Science and Technology department at University of Nigeria Nsukka. In addition, all the reagents were of analytical reagent grade unless otherwise stated. Distilled water was used in the preparation of solutions and dilution. Thus, physicochemical analyses were performed in triplicate determinations.

Pasteurization

Pasteurization of banana juice and banana beers was carried out at 95oC for 5 seconds. Mercury thermometer was used to check for the desired temperature readings.

Sugar content

Sugar contents in oBrix were measured using calibrated refractometers. Distilled water was used to check whether the refractometer readings were accurate. One drop of distilled water was dropped on the reading surface of the refractometer, and the reading was zero. There after the normal reading was obtained, the instrument was used to check for sugar content of banana juice, wort, and banana beer.

Fermentation

Fermentation was conducted by inoculation with dry yeast (Brewer’s yeast): 1g/L of wort of sorghum flour with banana juice. The ratios of worth and banana juice amounts were provided in the design expert’s formulation (Table 2). The alcohol content upon fermentation data were obtained using top fermentation since Ale yeasts (Saccharomyces cerevisiae) prefer top fermentation. Prior to fermentation, all raw material compositions such as proximate, sugar content, minerals, and vitamins were analyzed by the laboratory of food analysis to check the requirements for proper fermentation process based on yeast requirements for the optimum growth. The conditions for optimum activity were checked and the fermentation process was well achieved. The optimum pH, temperature control, and yeast pitching amount were all carried out properly to result in the desired improved banana beers.

pH reading

The desired pH readings were measured using a well calibrated pH meter. Firstly, the device was calibrated by using buffers of 4.0 and 7.0 before taking any reading. Secondly, the equipment was cleaned for each use using distilled water.

Temperature

Temperature measurements were obtained using a well calibrated thermometer.

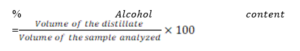

Alcohol content determination

The alcohol content was determined using the standard distillation method prescribed by Horwitz (2010). Distillation is a method for separating two or more miscible liquids based on their differences in boiling points. The amount of banana beer equaled to 100ml was put into the distillation flask (250ml) and other distillation apparatus were set up. Therefore, the alcohol was distilled at 78oC, and all samples were analyzed in triplicate. The percentage alcohol by volume was calculated as follows:

Moreover, the preliminary alcohol contents were detected using hand held Refractometer. The alcohol content is detected by subtracting the actual oBrix reading from initial oBrix. Indeed, every 2 oBrix decrease indicated 1%alcohol content increase. This is due to S. cerevisiae strains conversion of maltose, glucose, galactose, mannose, fructose, sucrose, and maltotriose into ethanol and carbon dioxide gas (Walker and Stewart, 2016).

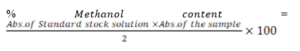

Methanol content determination

Methanol content in banana beer samples was determined using Spectrophotometric method (UV-Visible spectrophotometer) after treating methanol with Sodium Nitroprusside as a spectroscopic probe (Zhan et al., 2010). The principle of this method states that sodium nitroprusside (SNP) reacts with methanol in the sample to form a color-product in the basic solution that contains sodium hydroxide (NaOH). From the absorption of methanol stock solution of (2%) with SNP on 481nm, its absorbance reading was used as the reference to calculate the methanol content in the banana beer samples. The methanol concentration in the sample was proportional to the absorbance of the color-product formed.

Thus,

Sensory evaluation of banana beers produced

The sensory evaluation was based on the Hedonic scale ranking as described by Moskowitz and Sidel (1971). Sensory evaluation of banana beers was conducted to gain information regarding consumer preferences about the products. Therefore, 30 untrained panelists were asked to assess the beers. The assessors were made by 14 females and 16 males aged between 25-35 years were from Food Science and Technology department, University of Nigeria, Nsukka. Also, the number of assessors was in line with the number which is normally recommended between 25-75 panelists (O’sullivan, 2016). The panelists were informed about the objectives and asked not to take alcohol before. Sensory evaluation provided information about beer quality components and characteristics such as appearance, consistency, taste, aroma, and overall acceptability.

Color evaluation of banana beers produced

The Standard Reference Method (SRM) was applied to check for color variation among banana beers produced as well as their turbidity using UV-Visible spectrophotometer (Model: XY-ZW-752). Determination of SRM value involves measuring the attenuation of light of a particular wavelength (430 nm). The light pass through a 1 cm cuvette which contain a beer sample, and expressing the attenuation as absorption and scaling the absorption by a constant: 12.7 for the American Society of Brewing Chemists (Martínez et al., 2017).

Experimental design and data analysis

The experimental design was based on the mixture simplex lattice design. Design Expert software version 11 was used to generate experimental runs, restrictions, and equations that showed the variation of a response for a given level of any factor. The resulted means were separated using Duncan Multiple Range Test in Statistical Package for the Service Solution (SPSS) version 24.0. Data were presented as means ± standard deviation and the significance difference was accepted at p < 0.05. The mathematical model equation used to describe the relationship between factors and the response throughout this study is a 24 mixture equation which is presented as linear equation 1 (Rehman et al., 2014).

Results and Discussion

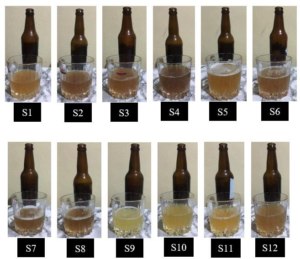

Different banana beer samples which were produced during the realization of this research are presented in Plate 1 while their formulation data were given in Table 2.

Physicochemical properties of banana beers produced

Physicochemical properties of the produced banana beers are presented in Table 3.

Alcohol content

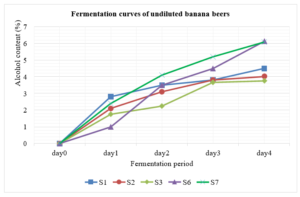

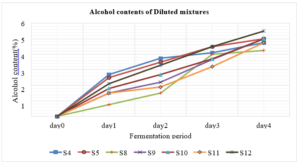

The values of alcohol content for banana beers produced were shown in Table 4. The alcohol contents ranged from 3.75±1.06 to 6.12±0.70 %. Right from the start, the sugar content before yeast pitching played a positive or negative response upon the fermentation process. Traditional banana beers were not diluted (S1, S2, and S3) as well as S6 and S7. Higher sugar content and gravity in undiluted samples inhibited the yeast growth. Thus, provided a poor fermentation process for non-malted mixture (Figure 3). Unfortunately, undiluted mixtures (S6 – S7) from improved banana beers showed good results of alcohol contents (Figure 4). This was a result of mashing of malted sorghum which gave higher amount of fermentable sugars: Maltose, Maltotriose, Sucrose, Fructose, Glucose. In addition, the highest alcohol content (S6) was obtained at the optimum pH of 4.15±0.07 (Table 3). Normally, the undiluted mixtures had higher sugar contents (oBrix) than diluted mixtures. Generally, the same issue of yeasts unable to hydrolyze complex sugars was obtained by (Navarro et al., 2007). In order to understand the inhibition better, let not forget that any problem which result in lower sugar conversion will definitely disturb the fermentation process. Willaert and Nedovic (2006) reported that glucose is consumed first at 60%, before other sugar molecules are consumed like fructose and maltose, respectively. Dilution of banana juice may provide a suitable way to increase glucose content in fermentable mixtures (Equation 2).

The information provided is that whenever the starting mixture had high TSS, and it intended up having high osmotic pressure caused by low water activity (aw). Thus, it becomes difficult for yeast to thrive in such environments. The higher TSS in the starting mixture, the higher TSS was observed in the final banana beers (non-fermentable sugars). However, there was no sample observed to have the final TSS of 0oBrix during the fermentation process (see Table 3). Furthermore, soluble solids other than fermentable sugars cannot be zero from the mixture. There was a linear relationship between TSS and sugar content. Thus, unfermented sugar content was reported as TSS, and it had an impact on other banana beer quality characteristics such as thickness, color, taste, and aroma, the same results were obtained by (Mosher & Trantham, 2017).

Table 3: Physicochemical properties of banana beers

Sample

TSS (o brix)

pH

T.A (%)

SRM

S1

24.00e±2.82

3.53a±0.14

0.19bcd±0.01

11.54e±0.40

S2

3.500ab±0.70

3.68a±0.04

0.23ef±0.01

6.89ab±0.54

S3

5.00abc±1.41

3.91ab±0.27

0.19bcd±0.01

6.62ab±0.04

S4

19.00d±1.41

3.61a±0.07

0.20bcde±0.00

12.14e±0.52

S5

6.00bc±0.00

4.60de±0.11

0.23ef±0.00

7.89c±0.52

S6

7.50c±0.70

4.15bc±0.07

0.29g±0.00

6.57ab±0.37

S7

2.50a±0.70

4.78e±0.05

0.25f±0.03

7.35bc±0.08

S8

2.00a±0.00

3.74a±0.10

0.18bc±0.01

6.08a±0.24

S9

2.00a±1.41

4.37cd±0.20

0.13a±0.02

8.86d±0.13

S10

5.00abc±1.41

4.59de±0.03

0.21cdef±0.02

7.24bc±0.17

S11

5.50bc±0.70

3.92ab±0.08

0.17b±0.02

6.88ab±0.80

S12

2.50a± 0.70

4.41cde±0.42

0.22def±0.00

6.20a±0.03

Values are means ± S.D of duplicate determinations, and values with the same superscripts showed no significant difference at p>0.05 under the same column. TSS: Total Soluble Solids, pH: potential Hydrogen, T.A: Titratable Acidity, and SRM: Standard Reference Method, S1-S3: Traditional banana beer samples, S4-S12: Improved banana beer samples.

Moreover, the results showed that the overtime sugar content of banana juice reduced as the alcohol content increased. The same results also were obtained for the pH impact on the overall fermentation process. The pH values of the starting mixtures were observed to reduce upon fermentation. In addition, the more acidic the pH tended to be, this had a negative impact on the alcohol production. The ANOVA results for a linear model suggested was not significant at p<0.05, the obtained p-value was 0.08, with Coefficient of Variation (CV) of 9.07%, R2, adjusted R2 of 0.59 and 0.42 respectively.

![]()

Table 4: Alcohol content of banana beers produced (%) 0.70abc 0.41ab 1.06ab 0.35abc 0.00bc 0.70d 0.17d 0.35abc 0.00bc 0.00bc 0.35abc 0.70c

Traditional banana beers

Improved banana beers

Sample

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

Alcohol vol.

4.50±

4.01±

3.75±

4.75±

5.00±

6.12±

6.08±

4.25±

5.00±

5.00±

4.75±

5.50±

Values are means ± S.D of triplicate determinations, and values with the same superscripts showed no significant difference at p>0.05. Alcohol Vol.: Alcohol content.

Table 5: Methanol content of banana beers (%) Methanol 0.76± 0.02e 0.42± 0.04c 0.68± 0.05de 0.66± 0.02d 0.02± 0.02a 0.02± 0.00a 0.05± 0.02a 0.19± 0.09b 0.05± 0.01a 0.01± 0.00a 0.68± 0.05de 0.15± 0.04b

Traditional banana beers

Improved banana beers

Sample

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

Values are means ± S.D of triplicate determinations, and values with the same superscripts showed no significant difference at p>0.05.

Figure 3: Fermentation process curves (Undiluted mixtures: S1, S2, S3, S6, and S7)

Figure 4: Fermentation process curves (Diluted mixtures: S4, S5, S8, S9, S10, S11, S12)

Methanol content

Methanol content results of banana beers are presented in Table 5. The values ranged from 0.01±0.00 % to 0.76±0.02 %. The prevalence of methanol content in traditional banana beers was moderately compared to that of improved banana beers (equation 3). Generally, during the extraction of banana juice, pectinase was used and this could have caused the rise of methanol content. The fact that banana juice obtained from this enzymatic process was not pasteurized might have increased the methanol contents of traditional banana beers. The effect of pectolytic enzymes on fermented beverages has been reported to induce an increase of methanol levels in products like ciders (Massiot et al., 1994) and wines (Bosso and Ponzetto, 1994). However, Nicolini et al., (1994) pointed out that yeast strains used during fermentation may play a crucial role to influence methanol production in alcoholic beverages. Furthermore, the study conducted by Ohimain (2016) on traditional alcoholic beverages pointed out that methanol production in traditionally fermented beverages can be linked to the activities of pectinase producing yeast, fungi, and bacteria. Thus, these methanol, fungi, and yeast producing organisms might have acted on the tradition banana juice to increase the response in traditional banana beers.

Heat treatment is required in order to deal with methanol prevalence in banana beers. In fact, banana juice must be pasteurized not only to kill possible antagonistic microorganisms to the yeast but also to inactivate some pectolytic enzymes that might be present. Therefore, the methanol contents of both traditional banana beers and improved banana beers showed a significant difference at p<0.05. Moreover, the methanol standard by World Health Organization suggests that the amounts between 6–27 mg/l in beers and 10-220 mg/l in spirits are not harmful, while FDA in USA accepts 0.1% of methanol content (Ohimain, 2016). The ANOVA for mean model suggested to monitor the amount of methanol in banana beer was not significant at p>0.05.

Sensory evaluation of banana beers produced

Sensory properties of banana beers are presented in Table 6. The appearance scores of the banana beers produced ranged from 4.30±1.78 to 6.80±1.57. Samples produced with malted sorghum and more inclusions of hops ranked higher in terms of appearance. Traditional banana beers had low appearance. This could be due to lack of malt and poor hydration of carbohydrates to give rise to simple sugars. Heating of natural simple sugars could give a desired color to the beer through the caramelization process.

Table 6: Sensory scores of banana beers Acceptability

Sample

Appearance

Taste

Consistency

Aroma

Overall

S1

5.75±1.12cd

4.85±1.31ab

5.25±0.85ab

5.50±1.76abc

5.05±1.14ab

S2

4.30±1.78a

4.40±1.67b

5.50±1.10abc

5.20±1.82ab

4.90±1.51ab

S3

4.55±1.39ab

4.85±1.31ab

4.90±1.07a

4.95±1.82a

4.60±1.39a

S4

6.10±1.29cd

5.30±1.78ab

4.75±1.65a

6.30±1.45bcd

5.40±1.90ab

S5

4.55±2.04ab

5.25±1.97ab

5.65±1.14abcd

6.15±1.38bcd

5.55±1.82ab

S6

4.30±2.23a

5.05±2.08ab

5.85 ±1.42bcde

6.00±1.55abcd

5.70±2.22abc

S7

5.15±1.66abc

5.55±2.45abc

5.90±1.55bcde

6.90±1.68d

5.35±2.25ab

S8

5.45±2.25bc

5.65±1.89bc

6.50±1.57def

6.95±1.27d

5.95±1.93bcd

S9

6.80±1.57d

6.85±1.81d

6.50±1.67def

6.40±1.50cd

7.00±1.29d

S10

5.50±1.05bc

6.05±1.43bcd

6.35±1.18cdef

6.45±1.35cd

6.95±1.23d

S11

5.85±0.98cd

6.55±1.27cd

6.95±1.19f

6.00±1.89abcd

6.75±1.33cd

S12

6.00±1.33cd

6.60±1.14cd

6.65±1.59ef

6.65±2.13cd

6.85±1.66d

1= Dislike extremely, 2= Dislike very much, 3= Dislike moderately, 4= Dislike slightly, 5= Neither like or dislike, 6= Like slightly, 7= Like moderately, 8= Like very much, 9= Like extremely; values under the same column with the same superscripts showed no significant difference at p>0.05, S1- S3: Traditional banana beer samples, S4-S12: Improved banana beer samples.

The appearance results of banana beers produced are presented in Table 6. The results were obtained based on assessors to rank the parameters according to color and preferences. Indeed, sorghum played a crucial role to give a desirable color change. Banana beers produced with roasted sorghum flour or roasted sorghum malt were highly appreciated by the assessors. This technology may be adopted to avoid the using of sugar caramel by most of the banana beer/ wine producers. Definitely, roasting sorghum is linked to give a good flavor to the banana beers.

The taste for banana beers produced ranked from 4.40±1.67 to 6.85±1.81 as it is presented in Table 6. Generally, 75% of traditional banana beers produced ranked below 5, while 100% of improved banana beers ranked at least 5 or above. This showed an improvement in the taste of banana beers produced with malted sorghum, hops, adequate water dilution, and controlled fermentation. The taste results clearly showed that high sugar content mixtures were not liked by sensory analysts, in addition, hops played a great role in enhancing the taste of improved banana beers.

The consistency scores of banana beers produced were measured by the panelists, and the obtained values ranged from 4.75±1.75 to 6.95±1.19, which are presented in Table 6.Traditional banana beers were ranked low for consistency compared to banana beers produced by the bioprocess fermentation method. This was possibly linked to non-malted sorghum flour and inadequacy dilutions used to produce traditional banana beers. Sorghum grit may have distorted the consistency of traditional banana beers, just because the flour which used it was not finely grinded.

The aroma of banana beers was ranked according to Hedonic scale, and the lowest score was 4.95±1.82 whereas 6.95±1.27 was the highest (Table 6). The least ranked formulation was made by 0.90; 0.10; 0; 0 while the highest ranked formulation was made by 0.70; 0.10; 0.05;0.15 which were banana juice, sorghum flour/ wort, hops and water respectively. The decrease of aroma profile may be caused by a lack of hops and malt in the formulation rather than it was caused by the high sugar content mixtures. However, yeast, malt and hops were reported to be the major components that result to provide the aroma to the beer (Holt et al., 2019).

The overall acceptability scores of banana beers produced were ranged from 4.60±1.39 to 7.00±1.29 (Table 6). The response variation upon different treatment was given in equation 4. From the mixture formulations, it was clear that the formulation which did not include hops and water dilution resulted in the lowest overall acceptability due to poor processing mixture formulations of some traditional banana beers. Malting, water dilution and adequate use of hops in banana beer production resulted to improve the overall acceptability of banana beers. Therefore, ANOVA for Quadratic model suggested to monitor the overall acceptability results had a p-value of 0.51 which was not significant at p>0.05. However, R2, adjusted R2 and C.V. results were 0.94, 0.44, and 8.19% respectively indicated an adequate signal of the model which can be used to navigate the design space.

![]()

Conclusion

In this study, traditional and improved banana beers were produced. The bioprocess fermentation method enhanced the quality and safety of traditional banana beers. This could depend on the mixture factors and processing conditions. Malting and mashing of sorghum enhanced both alcohol content and sensory characteristics. Moreover, the role of yeast cannot be overemphasized, since they are the ones to ferment the mixture. Nevertheless, sorghum protein had little impact on banana beer’s foaming properties as indicated by sensory scores on the appearance. The mixture formulation which could give the maximum alcohol content, Optimum pH, lowest methanol, and maximum overall acceptability was found to be at 0.68, 0.20, 0.02, and 0.1 for A, B, C, and D respectively. Thus, in order to obtain a better quality of banana beer, several parameters should be optimized such as pH, temperature, nutrients, and flavor as well as lowering microbial contamination. Protein quality on foaming properties and microbial enumeration of improved banana beer should be studied.

Ethical approval: I decree that this manuscript is an original paper, and it has never been published in any journal. The manuscript does not involve in Humans or animal rights violation.

Consent to participate: This manuscript is not applicable to human involvement subjects. No human or animals used during research and implementation of this research.

Consent to Publish: There is no data obtained using consent forms from individuals, guardians or other third parties.

Author’s contributions

Mr. Thierry Uzabakiriho performed conceptualization, experimental design, Data collection, analysis, and result interpretation as well as writing. In addition, He drafted the first draft of the manuscript.

Dr. (Mrs) Uzodinma Eunice Uche Osinachi performed writing – supervision of research, review, and editing.

However, all authors read and approved the final manuscript.

Funding: We thank Deutscher Akademischer Austauschi Dienst (DAAD) for sponsoring this research.

Availability of data and materials: Data and materials will be made available on reasonable request.

Conflict of interest: The author declares that there are no conflicts of interest.

References

- Bosso, A., & Ponzetto, L. (1994). Macerazione delle bucce in presenza di enzimi pectolitici del commercio, influenza sull’andamento della fermentazione alcolica dei mosti e sulle caratteristiche olfattive dei vini. Revista de Viticoltura Ed Enologia, 3, 45–66.

- Food and Agriculture Organization (FAO). (2020). Banana market review: preliminary results 2019. FAO Rome.

- Holt, S., Miks, M. H., de Carvalho, B. T., Foulquie-Moreno, M. R., & Thevelein, J. M. (2019). The molecular biology of fruity and floral aromas in beer and other alcoholic beverages. FEMS Microbiology Reviews, 43(3), 193–222.

- Horwitz, W. (2010). Official methods of analysis of AOAC International. Volume I, agricultural chemicals, contaminants, drugs/edited by William Horwitz. AOAC International,1.

- Kubo, R., & Kilasara, M. (2016). Brewing Technique of Mbege, a Banana Beer Produced in Northeastern Tanzania. Beverages, 2(3), 21. https://doi.org/10.3390/beverages2030021

- Kumar, S., Renumol, V. G., & Balakrishnan, K. (2018). Design and Development of a Knowledge-Based System for Diagnosing Diseases in Banana Plants. In Advances in Machine Learning and Data Science (pp. 239–250). Springer.

- Martínez, A., Vegara, S., Martí, N., Valero, M., & Saura, D. (2017). Physicochemical characterization of special persimmon fruit beers using bohemian pilsner malt as a base. Journal of the Institute of Brewing, 123(3), 319-327.

- Massiot, P., le Quéré, J. M., & DRILLEAU, J.-F. (1994). Biochemical characteristics of apple juices and fermented products from musts obtained enzymatically. Flüssiges Obst, 61(4), 108–113.

- Mosher, M., & Trantham, K. (2017). Brewing science: A multidisciplinary approach. Springer.

- Moskowitz, H. R., & Sidel, J. L. (1971). Magnitude and hedonic scales of food acceptability.

- Journal of Food Science, 36(4), 677–680.

- Navarro, S., Pérez, G., Navarro, G., Mena, L., & Vela, N. (2007). Variability in the fermentation rate and colour of young lager beer as influenced by insecticide and herbicide residues. Food Chemistry, 105(4), 1495–1503.

- Nicolini, G., Versini, G., Mattivi, F., & Dalla Serra, A. (1994). Glicosidasi in mosti e vini.

- Ohimain, E. I. (2016). Methanol contamination in traditionally fermented alcoholic beverages: the microbial dimension. Springerplus, 5(1), 1–10.

- O’sullivan, M. (2016). A handbook for sensory and consumer-driven new product development: innovative technologies for the food and beverage industry. Woodhead Publishing.

- Rehman, M. A., Khan, M. R., Sharif, M. K., Ahmad, S., & Shah, F.-H. (2014). Study on the storage stability of fruit juice concentrates. Pakistan Journal of Food Sciences, 24(1), 101–107.

- Walker, G., and Stewart, G. (2016). Saccharomyces cerevisiae in the production of fermented

beverages. Beverages, 2(4), 30. - Willaert, R., & Nedovic, V. A. (2006). Primary beer fermentation by immobilised yeast—a review on flavour formation and control strategies. Journal of Chemical Technology & Biotechnology: International Research in Process, Environmental & Clean Technology, 81(8), 1353–1367.

- Zhan, Y.-Y., Zhang, Y., Li, Q.-M., & Du, X.-Z. (2010). A Novel Visible Spectrophotometric Method for the Determination of Methanol Using Sodium Nitroprusside as Spectroscopic Probe. Journal of the Chinese Chemical Society, 57(2), 230–235. https://doi.org/10.1002/jccs.201000035