Publication Information

ISSN: 2641-6816

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2018

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Influences of Different Storage Conditions on Postharvest Quality of Mango (Mangifera indica L. cv. Sein Ta Lone)

P.P. Lei Yi1, T. T. Soe2*, Y.Yamamoto3, KT.D Myint1

1Department of Horticulture, Yezin Agricultural University, Naypyidaw, Myanmar

2Department of Food Science and Technology, Yezin Agricultural University, Naypyidaw, Myanmar

3Kochi University, JICA-TCP, Yezin Agricultural University, Naypyidaw, Myanmar

Received Date: September 26, 2019; Accepted Date: 3 October 02, 2019; Published Date: October 11, 2019

*Corresponding Author: T. T. Soe, Department of Food Science and Technology, Yezin Agricultural University, Naypyidaw, Myanmar. Tel: +95 9 250801932; Email: thansoesoe@gmail.com

Citaion: Lei Yi PP, Soe TT, Yamamoto Y, Myint KTD (2019) Influences of Different Storage Conditions on Postharvest Quality of Mango (Mangifera indica L. cv. Sein Ta Lone). Adv Nutri and Food Sci: ANAFS-148.

Abstract

Mango (Mangifera indica L.) is one of the most exportable fruits in Myanmar. “Sein Ta Lone” (STL) mango is the most popular variety and the highest postharvest losses due to the most perishable fruit. The objectives of this study are to investigate respiration and ethylene production rates of STL mango and to assess the postharvest quality and storage life as affected by different storage conditions. The wrapping materials were foam net sack and paper; non wrapped fruit was treated as control. The fruits were stored at room temperature and the optimum cold storage temperature of mango at 13˚C. Treatments were laid out by factorial arrangement in randomized complete block design with four replications. The data on weight loss, color index, skin firmness, Brix%, total titratable acidity, respiration rate, ethylene production and shelf life were analyzed. The fruits stored at 13˚C significantly showed the longer shelf life than those stored at room temperature. There were no significant differences in color index and shelf life of fruits among the wrapping treatments at room temperature. Thus, STL mango can be stored the shelf life of 7 days at ambient condition (36˚C, 50% RH) and 14 days at 13˚C.The ethylene production and respiration rates of STL mango under 13˚C were considerably lower than that of room temperature storage. The ethylene production and respiration rates were not significantly different among the wrapping treatments at respective temperatures. The minimum rate of respiration and ethylene production of untreated mango were 10.37 mg kg-1hr-1 and 0.24 ul kg-1hr-1, respectively. The results were revealed that net sack wrapping could be used at room temperature storage due to lower weight loss and ethylene production rate while paper wrapping could be used at cold temperature storage of 13˚C due to lower ethylene production and respiration rate with higher value of color index than other treatments.

Keywords: Ethylene; Mango; Post harvest Quality; Respiration Rate; Shelf Life; Storage Temperatures; Wrapping Materials

Introduction

Mango belongs to the family Anacardiaceae and it is originated in Indo-Burma region. Mango is an important tropical fruit around the world. Myanmar is the 6thlargest country in mango production in Asia. Mango is one of the most important commercial and exportable fruits in Myanmar. More than three hundred varieties of mango are cultivated throughout Myanmar [1]. Among these varieties, Sein Ta Lone is a popular variety for both domestic consumption and export markets. The export markets are China, Taiwan, Russia and Singapore. The postharvest losses of mango have been estimated in the range of 25-40 % from harvesting to consumption stage [2].

Mango possesses a very short storage life. The shelf life of mango can vary depending on varieties and storage conditions [3]. It ranges from 4-8 days at room temperature and 14- 21 days in cold storage at 13˚C depending on cultivar [4]. According to [5], the shelf life of Sein Ta Lone mango is 7 days under ambient condition without any treatment. It is a climacteric fruit and the ripening of mango fruit can be delayed by reducing respiration, ethylene production and elimination of mechanical damage [6]. The respiration is ametabolic process where organic material in living cells are continuously broken down by utilizing O2 and evolving CO2, H2O and energy during respiration. Fruit respiration rate is a necessary parameter for designing storage conditions [7].

Temperature is the most important environmental factor in shelf life of fresh fruits. Low temperature storage can decrease respiration rate and that can prolong the shelf life of fruit. Furthermore, proper storage environment has great impact on reducing postharvest losses, extension of postharvest life and retaining quality of fruits. Storage at suitable temperature, relative humidity and packaging materials are the key factors for good quality fruits [8]. Myanmar mangoes have limited storage life and increased postharvest losses due to improper handling practices and packaging system during transportation is still weak. According to [9] individual crop has a substantial range in rates of respiration and subsequently ethylene production. Thus, academic information on the measurements of the respiratory response and ethylene production of Sein Ta Lone mango is important in determining storage condition of prolonging the shelf life and to design the storage system. In consideration to these consequences, this research was carried out to investigate respiration rate and ethylene production of Sein Ta Lone mango and to determine postharvest quality as affected by wrapping materials and storage temperatures.

Materials and Methods

The experiment was conducted during April to May, the harvest season of Sein Ta Lone mango at the Laboratory of Horticulture Department, Yezin Agricultural University (YAU), Nay-Pyi-Taw, Myanmar. Physiologically matured (115-120 days after flowering) and freshly harvested “Sein Ta Lone” fruits were procured from the Myanadi mango orchard under Department of Agriculture at Kume Township in Mandalay Region. It took 20 hours by car from the orchard to the experimental site. The uniform fruits were selected for in size and shape, each weighing in the range of 320 to 350 grams without any defects. The sample fruits were washed by manually with distilled water to remove field heat, latex and dust and to reduce microbial population. The experiment was allocated in factorial randomized complete blocked (RCB) design with four replications. The first factor was wrapping materials: foam net sack wrap, paper wrap and non-wrapped fruit was treated as control fruit. The second one was treated as storage temperatures of room at (36˚C, 50% RH) and the optimum storage temperature of mango at 13 ˚C and 95% RH. A total of 528 fruits were divided into two groups for ambient condition and low temperature of 13˚C and each group was then divided further into three subgroups which consisted of 40 fruits. From each treatment, ten sample fruits were used to assess the data on physiological weight loss (%), color index, ethylene production, respiration rate and shelf life. Weight of sample fruits was measured and recorded using electronic digital balance. Physiological weight loss (%) was determined by equation. The respiration and ethylene production rates were measured by using the gas chromatograph (Simadzu, GC 7100) equipped with thermal conductivity detector (TCD) and Porapack Q column (Make: Chromatopak) and a flame ionization detector (FID) with the operation of 60˚C column temperature and 100˚C injection temperature, respectively. For gas analysis, one sample mango fruit was sealed in a 2 liter plastic container covered with silicon cap with an incubation time of 6 hours at ambient condition and 13˚C.The 5 ml gas sample was withdrawn with a gas–tight hypodermic syringe and analyzed for ethylene production and the unit was expressed in µl C2H4 kg-1hr-1andml CO2 kg-1hr-1for CO2production, respectively. The standard gases were used for at the initial stage of each measurement. All data were collected at two- day intervals from the beginning to the end of the experiment.

Surface color values will be measured by using colorimeter at three random points from the equatorial portion of the fruits. Changes in peel and pulp color were determined using a Minolta NR-20XE precision colorimeter taking the a*, b* and L* values for the determination of color index value. Shelf life was taken as the number of days that the fruits remained in a marketable condition judged by visual inspection of appearance. From each treatment, eight sample fruits were used to assess data on fruit firmness (kg/cm²), Brix (%) and total titratable acidity (TTA %). Measurement of fruit firmness was measured by puncturing into the fruit for three places at the equatorial portion with fruit hardness tester. The total soluble solids were determined by hand held digital pocket refract meter (Atago 3810 PAL-1). Homogenous juice sample was prepared by blending the peeled mango flesh in a blender. The juice sample was thoroughly mixed and a few drops were taken on prism of refractometer and direct reading was taken. The acidity of the sample fruit was determined by taking 10 ml sample into 100ml volumetric flask and volume was made up with distilled water. Then 10 ml of sample was taken into conical flask was titrated against alkali such as 0.1N NaOH solution, along with 1-2 drops of phenolphthalein indicator according to [1]. The collected data were statistically analyzed by using Excel program and Statistix version 8. The treatment means were compared by using Least Significant Difference (LSD) at 5% level.

Results and Discussion

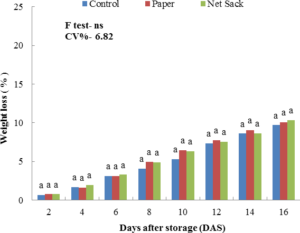

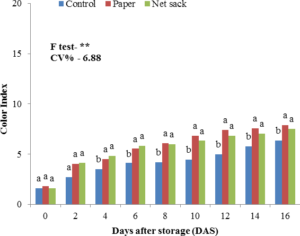

With the regardless of wrapping materials, the weight loss and the peel color development were highly significant between the storage temperatures. However, the highest physiological weight loss was observed in the fruits of unwrapped fruits stored at room temperature and these fruits reached full ripening stages of yellow color at 4 days after storage (Figure 1 and Figure 2). The color index value was increased in all treatments stored at ambient condition at 4 days after storage. Generally, the color index of fruits stored at 13˚C was lower value than that of the ambient condition. With the regardless of temperature, wrapping treatments showed considerable higher value in color index than unwrapped fruit.

(a)

(a)

(b)

(b)

Figure 1: Effects of wrapping materials on weight loss of Sein Ta Lone mango at (a) room temperature 13˚C.

(a)

(a)

(b)

Figure 2: Effects of wrapping materials on color index of Sein Ta Lone mango (a) at room temperature (b) at 13˚C.

There was no significant difference in skin firmness of fruits among the wrapping treatments at the respective temperatures. However, it can be assumed that the skin firmness of paper wrapping was a little higher value than others at the end of storage life at both temperatures (Table 1). This finding was in line with [10]. Which were stated that packaging materials at refrigeration storage can retard mango fruit softening.

|

Treatments |

Room temperature | At 13˚C | |||

| Skin firmness (kg/cm²) | Skin firmness (kg/cm2) | ||||

| 0DAS | 8DAS | 0DAS | 8DAS | 14DAS | |

| Non- wrapped | 4.80 a | 1.77 a | 4.80 a | 2.53 a | 1.97 a |

| Paper | 4.80 a | 1.90 a | 4.80 a | 2.31 a | 2.00 a |

| Net sack | 4.70 a | 1.69 a | 4.70 a | 2.96 a | 1.90 a |

| F- test | ns | ns | ns | ns | ns |

| LSD0.05 | 0.29 | 0.5 | 0.29 | 0.77 | 1.05 |

| CV% | 3.53 | 16.26 | 3.53 | 17.25 | 31.15 |

| *significant at 5% level ns = non-significant DAS = Days after storage Means in the same column by the same letters are not significantly different at P≤0.05. |

|||||

The change in total titratable acidity of Sein Ta Lone mango recorded during storage at ambient temperature and cold temperature of 13˚C was shown in (Table 2). There was no significant difference in Brix% and TTA % of the fruits among the wrapping materials at both temperatures. However, the Brix% of without wrapping treatment showed higher value than other treatments. The finding of [11] reported that mango is a climacteric fruit and it has a tendency to increase soluble solid concentration until ripe stage and showed slight reduction towards senescence stage. Mango fruits stored at 13˚C of low temperature maintained acidity content [5].

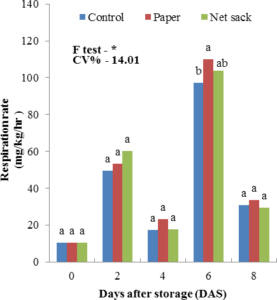

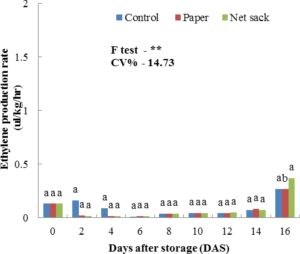

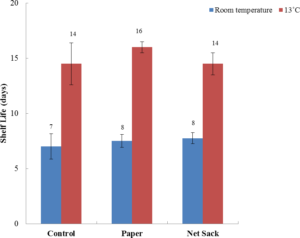

There was significant difference in shelf life of fruits between two temperatures. However, there was no significant difference in the shelf life of mango (7 days) among the wrapping treatments at room temperature. The fruits wrapped with paper showed the longest shelf life of 16 days stored at 13˚C. Therefore, the lower the storage temperature, the longer the storage life was observed (Figure 5). The minimum rate of respiration and ethylene production of untreated fruits were 10.37 ml CO2 kg-1hr-1 and 0.24µlC2H4kg-1hr-1 respectively (Figure 4). It was found that ethylene production rate of mango increased from 0.1-0.2 to1-3 µl C2H4 kg-1hr-1at 20°C [12]. The reason may be the rise in respiration and ethylene production during the climacteric is related to fruit ripening process.

|

Treatments |

Room temperature | At 13˚C | |||||||||

| Brix ( % ) | TTA ( % ) | Brix ( % ) | TTA ( % ) | ||||||||

| 0DAS | 8DAS | 0DAS | 8DAS | 0DAS | 8DAS | 14DAS | 0DAS | 8DAS | 14DAS | ||

| Non-wrapped | 5.17 a | 12.53 a | 1.00 a | 0.09 a | 5.17 a | 11.00a | 14.43 a | 1.04 a | 0.73 a | 0.48 a | |

| paper | 5.52 a | 10.95 a | 1.03 a | 0.07 a | 5.52 a | 13.24 a | 13.95 a | 1.03 a | 0.61 a | 0.38 a | |

| Net sack | 5.50 a | 10.19 a | 1.05 a | 0.09 a | 5.50 a | 11.08a | 14.75 a | 1.05 a | 0.80 a | 0.48 a | |

| F- test | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | |

| LSD0.05 | 0.35 | 2.53 | 0.04 | 0.03 | 0.35 | 2.44 | 1.49 | 0.04 | 0.46 | 0.16 | |

| CV% | 3.82 | 13.06 | 2.73 | 22.51 | 3.82 | 12.01 | 6.01 | 2.73 | 37.4 | 21.15 | |

Means in the same column by the same letters are not significantly different at P≤0.05. |

|||||||||||

The respiratory peak in “Sein Ta Lone” mangoes was observed at 6 days after storage in all treatments and the fruit ripens within 6 or 7 days. According to [13], mango is a climacteric fruit, exhibiting a climacteric pattern of respiration and an increase in ethylene production during ripening. The highest respiration rate of 110 ml CO2 kg-1 hr-1 was observed on the fruits of paper wrapping and followed by the fruits of the foam net sack stored at room temperature (Figure 3). There were significant differences in respiration and ethylene production rates of fruits at both temperatures. The respiration and ethylene production rates of “Sein Ta Lone” mangoes were decreased at low temperature storage of 13 ˚C which can prolong the shelf life. It was observed that mango fruits stored at low temperature showed lower ethylene production and respiration rate than high temperature storage [14, 15].

(a)

(b)

Figure 3: Effects of wrapping materials on respiration rate of Sein Ta Lone mango (a) at room temperature (b) at 13˚C

(a)

(a)

(b)

(b)

Figure 4: Effects of wrapping materials on ethylene production of Sein Ta Lone mango (a) at room temperature (b) at 13˚C.

Figure 5: Effects of wrapping materials on shelf life of Sein Ta Lone mango at different storage temperatures.

Conclusion

For Sein Ta Lone mango, the highest respiration rate was about 80 ml CO2-1kg-1hr for untreated fruit, 110 mg CO2-1kg-1hr for paper wrapping and 105 mg CO2-1kg-1hr or net sack wrapping at 6 days after storage of ambient condition. However, the highest respiration rate was observed about 60 mg CO2-1kg-1hr for all fruits with or without wrapping at 6 days after storage of 13˚C. The highest ethylene production was about 0.8 ul C2H4-1kg-1hr at 2 days after storage of ambient condition whereas all treatment stored at 13˚C did not show significant amount of ethylene production (0.1 ul C2H4-1kg-1hr) till 12 days after storage. Thus, it can be concluded that the rate of respiration and ethylene production were decreased with decrease in temperature. This study showed that the respiration rate and ethylene production were the important factors to determine the use of suitable wrapping materials at ambient and cold storage condition for mango fruits. There was no significant difference in fruit firmness, TTA% and Brix% among the treatments at the respective temperatures.

It can be concluded that in comparison of storage temperature, the control fruits stored at 13˚C significantly showed the longer shelf life of 14 days than that of room temperature (7 days). Sein Ta Lone mango treated with wrapping materials can be prolonged one day at room temperature and it can be prolonged for 7 days at 13˚C without wrapping treatment. The physiological weight loss% of fruits at room temperature was higher than that of at 13˚C due to faster water loss from skin evaporation and respiration rate. The respiration rate and ethylene production rate of Sein Ta Lone mango under room temperature storage were two times higher than those of 13oC. Therefore, net sack should be used at room temperature storage due to lower weight loss and ethylene production rate than other treatments. Moreover, paper wrapping should be used at cold temperature storage of 13˚Cdue to lower ethylene production and respiration rate with higher value of color development than other treatments.

Acknowledgements

The author would like to show sincere thanks to Japan International Cooperation Agency (JICA-TCP), Technical Cooperation project not only for financial support but also technical support during the research study. I would like to express my sincere gratitude to supervisor for technical support, valuable suggestions and critical check for this manuscript to improve this research. Moreover, I would like to extend sincere thanks to Professor of Horticulture Department, YAU for her valuable suggestions and administrative support.

References

- Vegetables and Fruits Research Development Centre (VFRDC) (2003) Annual report of fruits and vegetables research and development center, Myanmar Agriculture Service, Ministry of Agriculture and Irrigation.

- Food and Agricultural Organization (FAO). (2001). Food Balance Sheets. In: Economic and Social Development Department, Food and Agriculture Organization of United Nations, Viale delle Terme di Caracalla, 00153rome, Italy, pp.14.

- Yantarasri T, Uthaibutra J, Sornsrivichai J, Kumpuan W, Sardsud, V, et al. (1994) Modified atmosphere packing by perforated polymeric film and its effect on physical properties of fruit. ACIAR Proc. No. 50: 438-440.

- Carrillo LA, Ramirez-Bustamante F, Valdez-Torres JB, Rojas- Villegas R, Yahia EM (2000) Ripening and quality changes in mango fruit as affected by coating with an edible film. J. Food Quality 23: 470-486.

- Soe TT (2008) Studies on improved methods of postharvest storage of mango fruits. Ph.D. Thesis, Department of International Agricultural Development, Graduate School of Agriculture, Tokyo University of Agriculture, Japan.

- Yahia EM, Ornelas-Paz JdeJ, Ariza FR (2006) The Mango. Editorial Triallas, Mexico City, Mexico. P. 224. (In Spanish).

- Nakamura N, Rao DVS, Shiina T, Nawa Y (2004) Respiration properties of tree-ripe mango under CA condition. Japan Agricultural Research Quarterly 38: 221-226.

- Reid MS (2002) “Ethylene in postharvest technology”. Postharvest Technology of Horticultural Crops, by Kader AA (ed.) 3rd Edition. University of California, Oakland, California, pp.149-162.

- Peiris KHS, Mallon JL, Kays SJ (1997) Respiratory rate and vital heat of some specialty vegetables at various storage temperatures. Hraflkhnology 7: 46-49.

- Nasrijal NH (1993) Effect of storage temperature on pectin depolymerization and softening of mango fruit. B.Sc., thesis, Department of Botany, University Kebangsaan, Bangi, Malaysia.

- Ayele L, Abegaz K, Yetneberk S (2012) Postharvest Ripening and Shelf Life of Mango (Mangifera indica L.) Fruit as Influenced by 1 Methylcyclopropene and Polyethylene Packaging. Ethiopian Journal of Agricultural Sciences 22: 26-44.

- Brecht JK, Yahia EM (2009) “Postharvest physiology”. The Mango: Botany, Production and Uses, by Litz R.E (ed.).Tropical Research and Education Center and Center for Tropical Agriculture, University of Florida. CAB International. pp. 484-516.

- Lalel HJD, Singh Z, Tan SC (2003) Maturity stage at harvest affects fruit ripening, quality and biosynthesis of aroma volatile compounds in Kensington Pride‟ mango. Journal of Horticultural Science and Biotechnology 78: 225-233.

- Kader AA (2002) “Modified atmospheres during transport and storage”. Postharvest Technology of Horticultural Crops edited by Kader, A.A (Ed.). Oakland: University of California, Division of Agriculture and Natural Resources Publication, 3311, pp.535.

- AOAC (1994) Official Methods of Analysis Association of Analytical Chemists. 111 North 19th Street, Suite 20, 16th Edi. Arlington, Virginia, 22209.