Publication Information

ISSN 2692-1529

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2019

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Comparative Study of Paddlewheels and Fine Bubble Diffuser Aeration Systems in Red Tilapia Aquaculture: Impacts on Management, Productivity, And Financial Performance

Desy Febrianti1, Fitriska Hapsari2*, dan Amiqatul Fikriyah1

1Aquaculture Department, Jembrana Marine and Fisheries Polytechnic, Bali

2Aquaculture Department, Jakarta Technical University Fisheries, Jakarta

Received Date: November 31, 2024; Accepted Date: December 11, 2024; Published Date: January 06, 2025.

*Corresponding author: Fitriska Hapsari, C Aquaculture Department, Jakarta Technical University Fisheries, Jakarta; Email: fitriskahapsari@gmail.com

Citation: Febrianti D, Hapsari F, Fikriyah AM (2024) Comparative Study of Paddlewheels and Fine Bubble Diffuser Aeration Systems in Red Tilapia Aquaculture: Impacts on Management, Productivity, And Financial Performance. Jr Aqua Mar Bio Eco: JAMBE-139

DOI: 10.37722/JAMBE.2024202

Abstract

The implementation of fine bubble diffuser technology is designed to enhance dissolved oxygen levels, addressing a common challenge in fish farming where high stocking densities can compromise water quality. This technology is anticipated to improve water quality, increase productivity, and boost profitability. This study aims to evaluate aquaculture management practices, productivity, and financial performance in red tilapia farming using paddlewheels and fine bubble aeration diffusers. A mixed-methods approach, incorporating both quantitative and qualitative analyses, is employed. The research is conducted at a freshwater fish farming facility in Boyolali Regency, Central Java, which utilizes intensive farming methods for tilapia. The introduction of the fine bubble diffuser has allowed for an increase in stocking density from 20 fish/m² to 100-150 fish/m². Despite the increased stocking density, the water quality in ponds equipped with the diffuser remained stable, with higher dissolved oxygen (DO) levels compared to ponds without the diffuser, which had lower densities. Ponds with the fine bubble diffuser demonstrated an eight-fold increase in productivity. Financial analysis revealed that these ponds generated seven times higher income, achieved faster return on investment, and had a lower break-even point (BEP), indicating greater profitability for farmers.

Keywords: Dissolved Oxygen, Economic Feasibility, Increased Income, Intensive Cultivation

Introduction

Research Background

Tilapia is the most widely cultivated freshwater fish globally, with evidence suggesting that it was cultivated long before carp. Since the mid-20th century, tilapia farming has expanded widely in tropical and subtropical regions. In Indonesia, tilapia ranks among the leading freshwater aquaculture commodities, with an annual production of 2–3 million tonnes (MMAF, 2020). As of 2022, Indonesia held the third-highest aquaculture production in Asia (FAO, 2016).

Tilapia offers several advantages as an aquaculture species, including genetic diversity, rapid growth rates, high meat yield, resilience to diverse environmental conditions, disease resistance, and low mortality rates. These characteristics have accelerated the commercialization and industrialization of tilapia farming. To further enhance productivity, efforts have focused on improving cultivation systems, particularly through intensive farming methods and high stocking densities.

High stocking density systems, however, present challenges such as organic matter accumulation due to residual feed and fish waste. This accumulation reduces water quality, adversely affecting the growth and survival of tilapia during the rearing period. One of the primary water quality concerns in high-density systems is maintaining adequate levels of dissolved oxygen (DO), which is a critical indicator of water quality. Technologies such as paddlewheels and aeration diffusers have been introduced to increase dissolved oxygen levels in these systems. Fine bubble diffusers, which utilize microbubble technology, improve oxygen transfer by creating a larger surface area for air-water contact. According to Batara et al. (2017), the microbubbles emitted by diffusers enhance water turbulence, facilitating better oxygen distribution throughout the medium.

Microbubbles offer unique advantages over conventional aeration methods, as their smaller diameter allows them to remain suspended in water longer, spreading oxygen more evenly. This horizontal distribution maximizes oxygen availability within the rearing environment (Tsuge, 2014; Lee et al., 2019) Yamada et al, 2005). Research by Wen et al. (2011) demonstrated that microbubble technology could reduce ammonia content in water by up to 95%. In addition to supporting aquaculture species, dissolved oxygen is vital for microorganisms, which rely on it to break down organic matter and toxic compounds such as hydrogen sulphide, nitrite, and other harmful organics (Wu et al., 1994;.Prasad et al., 2014; Boyd, 2015; Niu et al., 2016) The implementation of paddlewheels and fine bubble diffusers therefore serves a dual purpose: improving water quality and supporting optimal tilapia productivity.

This increase in productivity is anticipated to correlate with higher farmer income. As noted by El-Sayed (2013), intensive tilapia farming—characterized by high stocking densities, the use of formulated feed, and technological interventions such as paddlewheels and diffusers—tends to be more profitable than traditional farming methods. Furthermore, the application of nanobubbles in plants, freshwater and seawater fish, and mice shows promising potential (Ebina et al., 2013). However, the use of paddlewheels and diffusers presents certain challenges, including higher electricity consumption (Pramleonita et al., 2018) and difficulties in controlling food intake (Ebina et al., 2013), which in turn increase operational costsWhile few studies have explored the potential of fine bubbles in aquaculture, Heriyani et al. (2022) found that microbubbles helped maintain dissolved oxygen (DO) levels of nearly 5 mg/L over a 50-day experiment, resulting in higher tilapia biomass. However, intensive farming systems with higher stocking densities necessitate adjustments in farming practices, higher initial investments, and increased operational costs. In addition, Yaparatne et al. (2024) highlight the limited comparative analysis of nanobubble applications in fish and shrimp farming, stressing the need for studies that confirm the benefits of nanobubbles over traditional aquaculture methods.

For example, intensive vannamei shrimp farming with a stocking density of 400 shrimp/m² and the addition of nanobubble technology achieved a survival rate of 92%, compared to 75% without nanobubble use (Mauladani et al., 2020). The total biomass yield in nanobubble-supported ponds reached 2,255 kg, and the financial analysis showed a B/C (Benefit/Cost) ratio of 1.26, similar to systems with lower stocking densities (Aras et al., 2023). This suggests that nanobubble technology positively impacts production sustainability in high-density shrimp farming.

A comprehensive study on aquaculture technologies, such as paddlewheels and fine bubble diffusers, is therefore essential to assess their effects on technical management, productivity, and financial outcomes in tilapia farming. An integrated approach will provide valuable insights and support decision-making processes for tilapia farmers considering business expansion and technological adoption. However, this study is preliminary and highlights the need for further research to explore the full potential of nanobubble technology in tilapia farming. Future studies should focus on a deeper understanding of its effects and the optimal conditions for its application in aquaculture systems.

Scientific Approach

This research employed a case study approach within a specified timeframe and location. It was conducted at a freshwater fish farming company in Boyolali Regency, Central Java, focusing on red tilapia growth. Data collection took place during the rearing season from January 2021 to October 2022.

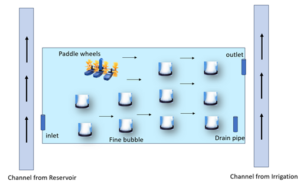

The study focused on assessing productivity increases in aquaculture ponds using an intensive cultivation system, specifically through the application of paddlewheels and aeration diffusers. These technologies influenced cultivation techniques, water quality, fish biomass, investment requirements, operating costs, and overall profitability. The theoretical framework guiding this study is outlined in Fig. 1.

Figure 1: Framework Research

Method

The case study methods employed included direct observation, participatory observation, interviews, documentation, and analysis of physical artifacts. Both direct and participatory observations were used to gather insights on site-specific situations and events that were not fully understood beforehand. Interviews enabled interaction with key stakeholders and provided a field-based perspective on implementation processes.

Three concrete ponds with soil or compacted soil bottoms were used for observation. Each pond measured 20 x 4 x 1.2 meters, with water levels maintained between 90–100 cm during the rearing period. Water for rearing was sourced from a nearby spring approximately 250 meters from the site, with an artesian well serving as a backup during the dry season. The ponds were designed with a flow-through irrigation system, in which water from the spring enters a main reservoir before flowing into the rearing ponds via an inlet. The inlet is positioned higher than the outlet to facilitate efficient water inflow and outflow, and the layout maximizes the flow from the reservoir to the rearing tanks.

Figure 2: Layout of The Paadhelwheel and Fine Bubble Diffuser in Cultivation Pond

Installation of the paddlewheels and diffusers was performed once the water level reached 70 cm. Each pond was equipped with one to two 1-horsepower paddlewheels and ten fine diffusers (Figure 2). Paddlewheels were positioned obliquely toward the outlet to encourage water circulation throughout the pond and assist in waste removal through the outlet. Rahmawati et al. (2021) noted that fine diffusers produce smaller-diameter bubbles than conventional aeration systems, thereby enhancing oxygen dispersion.

The diffuser was attached to a PVC pipe and weighted to prevent flotation during operation. The Fine Bubble Membrane Diffuser bubbles were generated by a Roots Blower, which transports air from an external source into the pond.

The grow-out process was conducted in several stages: container preparation, installation of paddlewheels and fine bubble diffusers, media preparation, seed stocking, feed management, water quality monitoring, growth monitoring, pest and disease control, and finally, harvesting and marketing (Table 1).

Table 1: Red Tilapia Cultivation Stages

| No | Stages | Methode |

| 1. | Preparation of cultivation ponds | a. The pool is cleaned by spraying it with water and dried for 1-2 days

b. Liming uses CaMg (CO3)2 dolomite lime at a dose of 50 g/m2. c. The lime that has been mixed with the soil throughout the pond is left for 1 day |

| 2. | Media preparation | a. After liming, the pool is filled with water and circulated

b. The pool is filled with water as high as 70 cm c. Providing moss seeds as initial natural food for fish seed |

| 3. | Installation of water wheel and fine diffuser

|

Installation of a 1 HP water wheel and fine diffuser at 10 points (Figure 3)

|

| 4. | Spreading of fry

|

a. Fry selection: fry aged 90 days, size 8-10 cm, weighing 20-25 g/head, and observing the morphology and movement of the seeds

b. Stocking density is between 100-150 individuals/m2 c. The acclimatization process was carried out for 10 minutes |

| 5. | Feeding | a. Feeding is done using the at satiation method with a frequency of feeding 3-5 times per day

b. The feed used is artificial floating feed of grower type (size 2 mm) and finisher (size 3 mm) c. Nutrient content: protein 31-33%, basic fat 5%, crude fiber <6%, ash <14% and water content <11%. d. Soaking is done before feed is given to the fish |

| 6. | Water quality management

|

a. Temperature measurements are carried out every day at 05.00 WIB and 14.00 WIB using a thermometer

b. pH and dissolved oxygen (DO) measurements are carried out every day at 05.00 WIB and 16.00 WIB using a pH meter and DO meter c. Checking for ammonia and nitrite is done once a week using the salifert ammonia test (The results of water quality checks during the maintenance period can be seen in Table 3) |

| 7. | Growth Monitoring | a. Growth monitoring is carried out once a week by sampling 20 fish

b. Sampling fish were weighed and measured to determine ADG, ABW and biomass values |

| 8. | Pest and disease control

|

a. Pests found at the location are cats, crabs and shellfish.

b. Collecting shellfish in the pond is done occasionally c. Treatment for sick fish is carried out by mixing fish food with a blended mixture of papaya leaves at a dose of 100 ppm |

| 9. | Harvest | a. Partial harvest method 5 times according to consumer demand and total harvest

b. The harvesting technique is carried out by closing the inlet and opening the outlet until the water is reduced by 80%. After that, the water wheel and fine diffuser are turned off and the harvest net or trawl is stretched as wide as the pon |

| 10. | Marketing | a. There are two methods: direct distribution to consumers and marketing to processing companies which are subsidiaries of the research location

b. Packaging using clear plastic contains 1/3 water and 2/3 oxygen so that the fish stay alive c. Transportation uses closed transportation |

Table 2 presents a comparison of red tilapia farming methods between the observed cycle and the previous cycle.

Table 2. Comparative Analysis of Cultivation Methods

| Methods | Pond with waterwheel and fine diffuser

|

Pond without waterwheel and fine diffuser

|

| Preparation of cultivation ponds | Installation of water wheel and fine diffuser | No Installation of water wheel and fine diffuser |

| Density

|

100-150 ind/m2

|

20 ind/m2

|

| Feeding

|

Feeding frequency 3-5 time/day | Feeding frequency 2-3 time/day |

| With enrichment | Without enrichment | |

| Water quality management

|

Parameters checked: temperature, pH, DO, nitrite, nitrate and ammonium. | Water quality checks are carried out once a day. Parameters checked: temperature and DO |

As shown in Table 2, several changes in the farming methods were implemented following the increase in stocking density, particularly in the stages of cultivation preparation, seed stocking, feeding, and water quality management. The most significant change in the cultivation preparation stage was the introduction of paddlewheels and fine bubble diffusers.

Data Analysis

This case study research utilizes descriptive analysis to provide a comprehensive description, explanation, and validation of observed activities. Key parameters observed during the study include water quality, feed management, pest and disease control, survival rate (SR), average body weight (ABW), average daily growth (ADG), feed conversion, productivity, biomass production, and investment costs related to the fine bubble diffuser. Financial indicators, including the R/C (Revenue/Cost) ratio, profit and loss analysis, and break-even point (BEP), were also analyzed.

Discussion

Cultivation Management

The installation of paddlewheels and fine bubble diffusers in the observation ponds was intended to stabilize oxygen levels throughout the rearing period. With the increase in stocking density to 150 fish/m², feed usage escalated to 3–5 feedings per day, compared to ponds with a stocking density of 20 fish/m². This higher feed usage, while necessary for maintaining fish growth, also contributes to the accumulation of uneaten feed and organic waste, which can lead to a decline in oxygen levels and an increase in toxic substances within the rearing medium.

Economically, the increased feed usage results in higher operational costs, potentially reducing overall profitability. The feed used during the rearing period was industrially produced, offering good nutritional quality but at a relatively high cost. This creates challenges for calculating the effectiveness of production costs, which in turn influences the financial analysis of the business (Bhujel, 2013). The financial implications of these changes will be further discussed in the next section.

The higher stocking density also limits the space available for the fish to move, potentially inhibiting their growth and well-being. Additionally, increased competition for oxygen is a critical factor to address when considering the effects of higher stocking densities in ponds.

Fine bubble technology has been proven effective in supporting increased aquaculture production by enabling higher stocking densities (Chirwa et al., 2024). However, elevated stocking densities in tilapia farming can degrade water quality, which adversely affects growth and survival rates (Pardiansyah et al., 2018; Arzad et al., 2019). Moreover, microbubbles can help mitigate ammonia levels in the culture medium (Scabra et al., 2022).

Therefore, the installation of paddlewheels is crucial for increasing the air-water contact area, particularly for enhancing surface oxygen transfer. In contrast, fine bubble diffusers produce smaller air bubbles that are more effectively dispersed throughout the water column, thereby improving oxygenation in the rearing medium.

As noted by Iskandar & Elrifadah (2015) water quality is a vital factor influencing both growth and survival rates in tilapia. The implementation of paddlewheels and fine diffusers in high-density ponds aims to maintain optimal water quality, ensuring it meets the physiological needs of tilapia throughout the rearing period. Similar studies have demonstrated that the use of microbubbles in other fish species, such as catfish, also helps maintain water quality within the appropriate range, thereby improving growth and survival rates when compared to ponds without microbubbles (Setyono et al., 2023).

Table 3 presents the results of the water quality measurements in the observation pond.

Table 3. Water Quality During Maintenance

| Parameter | Pond with waterwheel and fine diffuser | Pond without waterwheel and fine diffuser | Reference |

| Temperature (oC) | 23,8-28,8 | 26-30 | (Cavalcante et al, 2014) |

| pH | 6,7-7,5 | 6,7-7,2 | (Yanuar, 2017) |

| Dissolve Oxygen (mg/l) | >6,2 | > 3 – 5,25 | (Ashari et al., 2014), (Cavalcante et al 2014) |

| Ammonia (ppm) | 0,5 | 1,0 | (Parades-Trujillo et al, 2022) |

| Nitrite (mg/l) | 0,05-0,2 | >5 | (Kusmini et al., 2014) |

| Nitrate (mg/l) | 25-50 | ≤100 | (Caldini et al, 2015) |

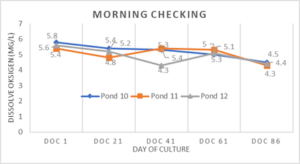

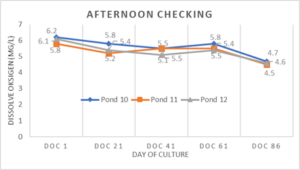

Figure 3: Dissolve Oksigen in Nile Tilapia Cultivation

The data presented in Table 3 indicate that, during the rearing period, the water quality in the observation ponds remained within the optimal range and was superior to that in ponds without the use of fine bubble diffusers.

A comparison of water quality in ponds using fine bubble diffusers with that in ponds not employing this technology reveals that, although ammonia levels were slightly higher in the ponds with diffusers, nitrate and nitrite concentrations were significantly lower. This outcome suggests that the presence of oxygen in the water facilitated the denitrification process, which helps convert ammonia into nitrite and nitrate (Pujihastuti, 2011; Wu et al., 1994). These findings support the notion that fine bubble diffuser technology can enhance water quality in aquaculture systems.

Moreover, the data in Table 3 show that dissolved oxygen (DO) levels in ponds equipped with fine bubble diffusers were consistently higher compared to those without the technology. DO measurements were conducted both in the morning, during the critical oxygen demand period, and in the afternoon, after phytoplankton photosynthesis had occurred. The DO levels measured in the morning were not significantly different from those in the afternoon, indicating that the combination of paddlewheels and fine bubble diffusers effectively stabilized oxygen levels throughout the day. Furthermore, daily DO monitoring during the rearing period, as depicted in Figure 4, showed stable oxygen levels throughout the observation period.

Dissolved oxygen (DO) measurements were taken daily using a DO meter, with values ranging from 4.3 to 5.9 mg/L (Figure 3). This range aligns with findings from previous studies indicating higher dissolved oxygen levels in ponds utilizing microbubble technology compared to those using conventional blowers (Rizky et al., 2022). The increase in dissolved oxygen is further enhanced by the application of circulation, which promotes the generation of microbubbles (Tekile et al., 2016)

Throughout the rearing period, dissolved oxygen levels in the rearing medium remained within the optimal range for tilapia. However, a slight decrease in DO levels was observed by week 13, likely due to the increasing age and size of the tilapia, which require more oxygen. With higher stocking densities, maintaining an adequate oxygen supply becomes crucial for tilapia survival.

In addition to improving DO levels, the use of fine bubble technology can also reduce the need for fertilizers in fish farming systems (Chirwa et al., 2024). Intensive farming systems with high stocking densities often result in the accumulation of drug residues in both fish feed and pond sediments, as well as antibiotic resistance genes in the pond environment, indicating moderate to high ecological risks (Zhou et al., 2020; M. Zhou et al., 2022; Wang et al., 2021). These findings underscore the ecological challenges associated with intensive aquaculture. However, the use of fine bubble technology can mitigate these risks by reducing drug residues, offering a more sustainable solution for aquaculture. Microbubbles, in particular, have demonstrated significant potential for large-scale applications in water and wastewater treatment (Kaushik & Chel, 2014).

Water quality is a critical factor in tilapia aquaculture, as optimal conditions help prevent stress, which can make fish more susceptible to disease (Abd El-Hack et al., 2022; Mramba & Kahindi, 2023). The integration of paddlewheels and fine bubble diffusers in intensive tilapia aquaculture systems represents an effective strategy for maintaining water quality, thereby providing a conducive environment for the growth and development of tilapia throughout the rearing period.

Productivity

The cultivation performance indicators observed during the study are summarized in Table 4 below.

Table 4. Production Performance

| Parameter | Pond without waterwheel and fine diffuser | Pond with waterwheel and fine diffuser | ||

| Pond 10 | Pond 11 | Pond 12 | ||

| Stocking amount (ind) | 2.000 | 10.000 | 15.000 | 15.000 |

| Pond wide (m2) | 96 | 96 | 96 | 96 |

| Stocking density (ind/m2) | 20 | 105 | 157 | 157 |

| Stock size (ind/kg) | 200 | 250 | 225 | 220 |

| Harvest size (ind/kg) | 4 | 4-5 | 5-6 | 5-6 |

| Biomass (kg) | 250 | 1.950 | 1.800 | 1.480 |

| Food Conversion Ratio (FCR) | 2,1 | 0,8 | 1,0 | 1,5 |

| Survival Rate (SR) (%) | 50 | 85 | 69 | 65 |

| ADG (gram/day) | 0,1-3 | 0,03-3,81 | 0,1-3,31 | 0,01-3,3 |

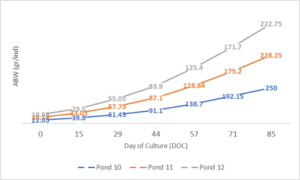

| ABW (gram/ind) | 20,10-250 | 22,05-250 | 20,15-228,25 | 19,95-222,75 |

| Productivity (kg/ m2) | 2,6 | 20,31 | 18,75 | 15,42 |

Based on the data presented in Table 4, a significant difference in production performance was observed between the ponds that used a fine bubble diffuser and those that did not. One notable difference was in the stocking density, where the observation pond with a fine bubble diffuser supported a 4-6 times higher stocking density compared to the pond without the diffuser.

The production performance in the observation pond was markedly higher than that in the pond without a fine bubble diffuser. Ponds with fine bubble diffusers demonstrated improved productivity, survival rate (SR), feed conversion ratio (FCR), and biomass. Among the three observation ponds, Pond 10 exhibited the highest productivity (20.31 kg/m²), the highest biomass (1,950 kg), the best FCR (0.8), and the highest SR (85%).

The observed increase in production performance in the observation ponds suggests that the higher stocking density did not induce stress in the fish. Firman et al. (2019) support this finding, indicating that the use of microbubbles in tilapia rearing, even at varying stocking densities, did not lead to abnormal blood glucose levels, a known indicator of stress in fish. According to Thomas et al. (2020), microbubbles can increase oxygen levels 25 to 44 times more effectively than macrobubbles. The prolonged presence of oxygen in the water reduces oxygen consumption during the breakdown of organic matter, thereby stabilizing water quality and improving the overall health and productivity of aquatic organisms.

The stable water quality throughout the rearing period further demonstrates that the increase in stocking density in the observation pond, particularly in terms of oxygen availability, was effectively managed. Insufficient oxygen in rearing environments can lead to reduced appetite and stunted growth as a stress response in fish (Monier et al., 2019). In the Litopenaeus vannamei, the final weight directly realated to duration of cultivation and dissolve oxygen, and inveresely related with density (Ruiz-Velazco, 2010).

When comparing the three observation ponds, Pond 10 exhibited the highest average weight gain, likely due to its relatively lower stocking density compared to the other two ponds (Fig. 3). Lower stocking density allows for more efficient growth, as it provides fish with greater space to move freely and access feed, thus enhancing feed consumption and promoting better weight gain.

Figure 4: Average Body Weight

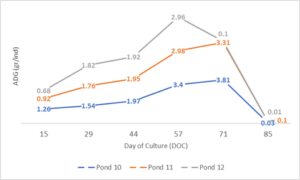

The daily growth data indicates a consistent increase in the Average Daily Growth (ADG) values (Figure 5). However, between Days of Culture (DOC) 15 and 44, a period of slow growth was observed, likely due to high-intensity rainfall, which negatively impacted water quality and reduced the fish’s appetite.

The average daily growth of Red Tilapia in Pond 10 ranged from 1.26 to 3.85 grams per day, which was higher compared to Pond 11, where ADG ranged from 0.92 to 3.53 grams per day, and Pond 12, which exhibited the lowest ADG values, ranging from 0.68 to 3.4 grams per day.

Figure 5: Average Daily Growth

In addition to monitoring growth and body weight gain, the low survival rates (SR) observed in Pond 11 and Pond 12 were attributed to fish mortality resulting from a disease outbreak. The affected fish exhibited symptoms such as protruding eyes, discoloration and peeling of dorsal fins, and an accelerated operculum opening compared to healthy fish. These symptoms led to impaired swimming ability and a weakened feeding response. Based on visual observations, the disease was suspected to be caused by Streptococcus sp. bacteria, commonly known as streptococcosis (Maulu et al., 2021; Debnath et al., 2023).

Financial Analysis

The application of the fine bubble diffuser technology in red tilapia aquaculture is anticipated to enhance business income and profitability. The following table will provide a financial analysis comparison between the red tilapia enlargement business that utilizes the fine bubble diffuser and one that does not.

Table 5. Financial Performance

| Parameter | Pond without waterwheel and fine diffuser | Pond with waterwheel and fine diffuser |

| Investment (Rp) | 213.475.000 | 213.475.000 |

| Total Cost (Rp/year) | 87.000.000 | 427.850.000 |

| Biomass (kg) | 3.000 | 20.920 |

| Shrimp Prices (Rp/kg) | 30.000 | 30.000 |

| Revenue (Rp) | 90.000.000 | 627.600.000 |

| Profit (Rp) | 3.000.000 | 199.750.000 |

| R/C rasio | 4,88 | 7,57 |

| ROI | 0,42 | 2,94 |

| NPV | 5.110.714 | 38.905.000 |

| BEP units (kg) | 13.200 | 1.382 |

| BEP price (Rp/kg) | 33.400 | 21.083 |

Based on the data presented in Table 5, it is evident that the income generated from the ponds utilizing the Fine Bubble Diffuser is significantly higher than that of the ponds without this technology. The increased income in the ponds equipped with the Fine Bubble Diffuser is attributed to improvements in survival rate (SR), harvest biomass, feed conversion ratio (FCR), and overall pond productivity (as shown in Table 4). Red tilapia farming with the Fine Bubble Diffuser resulted in a harvest biomass that was seven times greater than that from the ponds without the technology.

While the increased costs due to higher stocking density, additional feed, electricity, and the purchase of the waterwheel and Fine Bubble Diffuser did lead to a rise in operational expenses, the substantial increase in harvest biomass more than compensated for these costs. As a result, the total profit amounted to Rp 199,750,000 per year or Rp 49,937,500 per cycle.

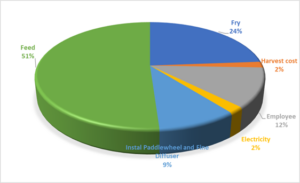

Total costs, which include the expenses for fish fry and feed, accounted for a significant portion of the production expenditure. Feed costs represented 50% of the total cost for each cycle. Although the increase in feed expenses affects profitability, the higher biomass yield more than offsets this cost, leading to a significant increase in revenue. Feed efficiency or feed conversion ratio is a key factor to profitability of Nile Tilapia (Omasaki et al, 2017).

The second-largest cost component after feed is the cost of purchasing seed. During the rearing period, male tilapia fry were used, as they exhibit a faster growth rate compared to female tilapia when raised monosexually (Khan et al., 2014). The fry used measured 8-10 cm in length, weighed 20-25 grams each, and were 90 days old. The price of the fry ranged from Rp 500 to Rp 520 per fish, and seed costs accounted for 23% of the total production costs.

The following figure presents the percentage distribution of cost utilization during the rearing period:

Figure 6: Percentage of Operational Costs for Red Tilapia Cultivation

The financial analysis of the observed ponds revealed that both the R/C ratio and ROI were significantly higher in ponds utilizing a pinwheel and fine bubble diffuser compared to those without these technologies. This indicates that increasing stocking density while employing a pinwheel and fine bubble diffuser results in higher profitability. Nonetheless, tilapia farming with a stocking density of 20 fish/m² remains a profitable venture for farmers.

Conclusion

Increasing stocking density in tilapia aquaculture has been found to enhance productivity and profitability. However, these benefits are most pronounced when high stocking densities are paired with optimized management practices. Key factors include the use of paddlewheels and fine bubble diffusers to maintain sufficient oxygen levels, effective feed management, regular water quality monitoring, and measures to prevent fish pests and diseases. Ensuring proper water quality throughout the rearing period is critical for the growth and health of the fish. Paddlewheels and fine bubble diffusers help not only to maintain oxygen levels but also to reduce nitrate and nitrite concentrations in the water. Given that this is a preliminary analysis, there is considerable potential for future research to statistically investigate the relationship between these management practices and aquaculture performance.

Credit Authorship Contribution Statement: Febrianti, Desy: writing original draft, writing-review and editing, funding acquisition. Hapsari, Fitriska: conceptualization, methodology, investigation, and formal analysis. Fikriyah, Amiqatul: visualization, writing review and editing.

Acknowledgment

The research was carried out thanks to good cooperation from several parties such as the Jakarta Fisheries Business Expert Polytechnic, Jembrana Marine Fisheries Polytechnic, and Agusau Fishfarm. We thank you very much for the support and assistance that has been provided. We would also like to express our thanks to Zulhamsyah Hadi Pradana, student of the Jakarta Fisheries Business Expert Polytechnic Aquaculture Technology Study Program for his assistance in collecting data at the research location.

Reference

- Abd El-Hack, M. E., El-Saadony, M. T., Nader, M. M., Salem, H. M., El-Tahan, A. M., Soliman, S. M., & Khafaga, A. F. (2022). Effect of environmental factors on growth performance of Nile tilapia (Oreochromis niloticus). International Journal of Biometeorology, 66(11), 2183–2194. https://doi.org/10.1007/s00484-022-02347-6

- Aras, A., Febrianti, D., Kiswanto, A., & Yudana, I. G. P. (2023). Analisa kelayakan usaha dan pemanfaatan permodalan blu-lpmukp pada budidaya udang vaname (studi kasus: Koperasi Cahaya Mina PKPJ). Jurnal Perikanan Unram, 13, 320–330. https://doi.org/10.29303/jp.v13i2.480

- Arzad, M., Ratna, R., & Fahrizal, A. (2019). Pengaruh padat tebar terhadap pertumbuhan ikan nila (Oreochromis niloticus) dalam sistem akuaponik. Median: Jurnal Ilmu Ilmu Eksakta, 11(2), 39-47.

- Ashari, C., Tumbol, R., & Kolopita, M. (2014). Diagnosa Penyakit Bakterial Pada Ikan Nila (Oreocrhomis niloticus) Yang Di Budi Daya Pada Jaring Tancap Di Danau Tondano. E-Journal BUDIDAYA PERAIRAN, 2. https://doi.org/10.35800/bdp.2.3.2014.5700

- Batara, K., Zaman, B., & Oktiawan, W. (2017). Pengaruh Debit Udara dan Waktu Aerasi Tehadap Efisiensi Penurunan Besi dan Mangan Menggunakan Diffuser Aerator Pada Air Tanah. Jurnal Teknik Lingkungan, 6(1), 1–10.

- Bhujel, R. C. (2013). Feed management practices for Nile tilapia in Thailand. On-Farm Feeding and Feed Management in Aquaculture, 159–189.

- Boyd, C. (2015). Water Quality: An Introduction. https://doi.org/10.1007/978-3-319-17446-4

- Caldini, N. N., Cavalcante, D. D. H., Rocha Filho, P. R. N., & Sá, M. V. D. C. E. (2015). Feeding Nile tilapia with artificial diets and dried bioflocs biomass. Acta Scientiarum. Animal Sciences, 37(4), 335-341.

- Chirwa, W., Li, P., Zhan, H., Zhang, Y., & Liu, Y. (2024). Application of fine bubble technology toward sustainable agriculture and fisheries. Journal of Cleaner Production, 449, 141629. https://doi.org/https://doi.org/10.1016/j.jclepro.2024.141629

- Debnath, S. C., McMurtrie, J., Temperton, B., Delamare-Deboutteville, J., Mohan, C. V., & Tyler, C. R. (2023). Tilapia aquaculture, emerging diseases, and the roles of the skin microbiomes in health and disease. In Aquaculture International (Vol. 31, Issue 5). Springer International Publishing. https://doi.org/10.1007/s10499-023-01117-4

- De Holanda Cavalcante, D., Caldini, N. N., da Silva, J. L. S., dos Santos Lima, F. R., & do Carmo, M. V. (2014). Imbalances in the hardness/alkalinity ratio of water and Nile tilapia’s growth performance. Acta Scientiarum. Technology, 36(1), 49-54.

- Ebina, K., Shi, K., Hirao, M., Hashimoto, J., Kawato, Y., Kaneshiro, S., Morimoto, T., Koizumi, K., & Yoshikawa, H. (2013). Oxygen and air nanobubble water solution promote the growth of plants, fishes, and mice. PloS one, 8(6), e65339. https://doi.org/10.1371/journal.pone.0065339

- El-Sayed, A.-F. M. (2013). On-farm feed management practices for Nile tilapia (Oreochromis niloticus) in Egypt. In M.R. Hasan and M.B. New, eds. On-farm feeding and feed management in aquaculture. FAO Fisheries and Aquaculture Technical Paper No. 583. Rome, FAO. 101–129.

- Food and Agriculture Organization. (2016). FAO yearbook. Fishery and aquaculture statistics. FOOD & AGRICULTURE ORG.

- Firman, S. W., Nirmala, K., Supriyono, E., & Rochman, N. T. T. (2019). Performance evaluation of micro bubble generator on physiological response of Nile tilapia Oreochromis niloticus (Linnaeus, 1758) farmed at different densities in recirculating aquaculture system. Jurnal Iktiologi Indonesia, 19(3), 425. https://doi.org/10.32491/jii.v19i3.504

- Heriyati, E. ., Rustadi, R. ., Isnansetyo, A. ., Triyatmo, B. ., Istiqomah, I. ., Deendarlianto, D. ., & Budhijanto, W. . (2022). Microbubble Aeration in A Recirculating Aquaculture System (RAS) Increased Dissolved Oxygen, Fish Culture Performance, and Stress Resistance of Red Tilapia (Oreochromis sp.). Trends in Sciences, 19(20), 6251. https://doi.org/10.48048/tis.2022.6251

- Iskandar, R., & Elrifadah, E. (2015). Pertumbuhan dan Efisiensi Pakan Ikan Nila (Oreochromis niloticus) yang Diberi Pakan Buatan Berbasis Kiambang. Ziraa’Ah, 40(1), 18–24.

- Kaushik, G., & Chel, A. (2014). Microbubble technology: Emerging field for water treatment. Bubble Science, Engineering & Technology, 5, 33–38. https://doi.org/10.1179/1758897914Y.0000000010

- Kusmini, I. I., Gustiano, R., & Putri, F. P. (2014). Hubungan Panjang dan Bobot Ikan Nila Lokal, Best F5 Dan F6 Di Pangkep, Sulawesi Selatan Pada Umur 60 Hari Pemeliharaan. Berita Biologi, 13(2).

- Lee, C. H., Choi, H., Jerng, D.-W., Kim, D. E., Wongwises, S., & Ahn, H. S. (2019). Experimental investigation of microbubble generation in the venturi nozzle. International Journal of Heat and Mass Transfer, 136, 1127–1138. https://doi.org/https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.040

- Mauladani, S., Rahmawati, A., Absirin, M., Saputra, R., Pratama, A., Hidayatullah, A., Dwiarto, A., Syarif, A., Junaedi, H., Cahyadi, D., Saputra, H., Prabowo, W., Kartamiharja, U., Noviyanto, A., & Rochman, N. (2020). Economic feasibility study of Litopenaeus vannamei shrimp farming: nanobubble investment in increasing harvest productivity. Jurnal Akuakultur Indonesia, 19, 30–38. https://doi.org/10.19027/jai.19.1.30-38

- Maulu, S., Hasimuna, O. J., Mphande, J., & Munang’andu, H. M. (2021). Prevention and Control of Streptococcosis in Tilapia Culture: A Systematic Journal of Aquatic Animal Health, 33(3), 162–177. https://doi.org/10.1002/aah.10132

- Monier, M., Hoseinifar, S. H., & Faggio, C. (2019). Fish response to hypoxia stress: growth, physiological and immunological biomarkers. Fish Physiology and Biochemistry, 45. https://doi.org/10.1007/s10695-019-00614-9

- Ministry of Marine Affairs and Fisheries (MMAF). 2020. Production Fisheries Indonesia.

- Mramba, R. P., & Kahindi, E. J. (2023). Pond water quality and its relation to fish yield and disease occurrence in small-scale aquaculture in arid areas. Heliyon, 9(6), e16753. https://doi.org/https://doi.org/10.1016/j.heliyon.2023.e16753

- Niu, T., Zhou, Z., Shen, X., Qiao, W., Jiang, L.-M., Pan, W., & Zhou, J. (2016). Effects of dissolved oxygen on performance and microbial community structure in a micro-aerobic hydrolysis sludge in situ reduction process. Water Research, 90, 369–377. https://doi.org/https://doi.org/10.1016/j.watres.2015.12.050

- Omasaki, S. K., Janssen, K., Besson, M., & Komen, H. (2017). Economic values of growth rate, feed intake, feed conversion ratio, mortality and uniformity for Nile tilapia. Aquaculture, 481, 124-132.

- Paredes‐Trujillo, A., & Mendoza‐Carranza, M. (2022). A systematic review and meta‐analysis of the relationship between farm management, water quality and pathogen outbreaks in tilapia culture. Journal of Fish Diseases, 45(10), 1529-1548.

- Pardiansyah, D., Widya, O., & Suharun, M. (2018). Pengaruh Peningkatan Padat Tebar Terhadap Pertumbuhan dan Kelangsungan Hidup Ikan Nila (Oreochromis niloticus) Menggunakan Sistem Resirkulasi. Jurnal Agroqua, 16(1), 81–86. https://journals.unihaz.ac.id/index.php/agroqua/article/view/364

- Pramleonita, M., Yuliani, N., Arizal, R., & Wardoyo, S. (2018). Parameter fisika dan kimia air kolam ikan nila hitam (Oreochromis niloticus). Jurnal Sains Natural, 8, 24. https://doi.org/10.31938/jsn.v8i1.107

- Prasad, B. S. R. V, Srinivasu, P. D. N., Varma, P. S., Raman, A. V, & Ray, S. (2014). Dynamics of Dissolved Oxygen in Relation to Saturation and Health of an Aquatic Body: A Case for Chilka Lagoon, India. Journal of Ecosystems, 2014(1), 526245. https://doi.org/https://doi.org/10.1155/2014/526245

- Pujihastuti, Y. (2011). Nitrification and denitrification in pond. Jurnal Akuakultur Indonesia, 10, 89. https://doi.org/10.19027/jai.10.89-98

- Rizky, P., Br Ritonga, L., Primasari, K., & Nasuki. (2022). Use of microbubble generator on the growth vannamei shrimp culture. IOP Conference Series: Earth and Environmental Science, 1036, 12081. https://doi.org/10.1088/1755-1315/1036/1/012081

- Ruiz-Velazco, J. M., Hernández-Llamas, A., & Gomez-Muñoz, V. M. (2010). Management of stocking density, pond size, starting time of aeration, and duration of cultivation for intensive commercial production of shrimp Litopenaeus vannamei. Aquacultural Engineering, 43(3), 114-119.

- Scabra, A., Afriadin, A., & Marzuki, M. (2022). Efektivitas Peningkatan Oksigen Terlarut Menggunakan Perangkat Microbubble Terhadap Produktivitas Ikan Nila (Oreochromis niloticus). Jurnal Perikanan Unram, 12, 13–21. https://doi.org/10.29303/jp.v12i1.269

- Setyono, B. D. H., Baihaqi, L., Marzuki, M., Atmawinata, L., Fitria, S., & Affandi, R. (2023). Microbubble Technology to Improve Growth of Catfish (Clarias sp.). Jurnal Penelitian Pendidikan IPA, 9, 7373–7382. https://doi.org/10.29303/jppipa.v9i9.3433

- Tekile, A., Kim, I., & Lee, J.-Y. (2016). Effect of microbubble generator operating parameters on oxygen transfer efficiency in water. Desalination and Water Treatment, 57, 1–9. https://doi.org/10.1080/19443994.2016.1178604

- Thomas, B., Ohde, D., Matthes, S., Engelmann, C., Bubenheim, P., Terasaka, K., Schlueter, M., & Liese, A. (2020). Comparative investigation of fine bubble and macrobubble aeration on gas utility and biotransformation productivity. Biotechnology and Bioengineering, 118. https://doi.org/10.1002/bit.27556

- Tsuge, H. (2014). Micro- and nanobubbles – fundamentals and applications. https://doi.org/10.4032/9789814463119

- Wang, B., Xie, K., & Lee, K. (2021). Veterinary drug residues in animal-derived foods: Sample preparation and analytical methods. Foods, 10(3), 555.

- Wen, L. H., Ismail, A. Bin, Menon, P. M., Saththasivam, J., Thu, K., & Choon, N. K. (2011). Case studies of microbubbles in wastewater treatment. Desalination and Water Treatment, 30(1), 1–7. https://doi.org/https://doi.org/10.5004/dwt.2011.1217

- Wu, R. S. S., Lam, K. S., MacKay, D. W., Lau, T. C., & Yam, V. (1994). Impact of marine fish farming on water quality and bottom sediment: A case study in the sub-tropical environment. Marine Environmental Research, 38(2), 115–145. https://doi.org/https://doi.org/10.1016/0141-1136(94)90004-3

- Yamada, S., Amano, T., & Minagawa, H. (2005). A study for distribution of microbubbles and effects of oxygen supplying into water. Nippon Kikai Gakkai Ronbunshu B Hen(Transactions of the Japan Society of Mechanical Engineers Part B)(Japan), 17(5), 1301-1306.

- Yanuar, V. (2017). Effect of Different Types of Feed on Growth Rate of Tilapia Fish (Oreochiomis niloticus) and Water Quality in The Aquarium Maintenance. Ziraa’ah, 42(2), 91–99.

- Yaparatne, S., Morón-López, J., Bouchard, D., Garcia-Segura, S., & Apul, O. G. (2024). Nanobubble applications in aquaculture industry for improving harvest yield, wastewater treatment, and disease control. Science of The Total Environment, 931, 172687. https://doi.org/10.1016/j.scitotenv.2024.172687

- Zhou, A., Zhang, Y., Xie, S., Chen, Y., Li, X., Wang, J., & Zou, J. (2020). Microplastics and their potential effects on the aquaculture systems: a critical review. Reviews in Aquaculture, 13. https://doi.org/10.1111/raq.12496

- Zhou, M., Hong, B., Li, J., & Yu, S. (2022). Fingerprinting pharmaceuticals of multiple sources at a provincial watershed scale. Science of The Total Environment, 820, 153356. https://doi.org/https://doi.org/10.1016/j.scitotenv.2022.153356