Publication Information

ISSN: 2641-6816

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2018

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Cassava Root Yield Losses Caused By Root Shape, Rot and Peeling and Cut-Off for Processing of Four Cassava Varieties on Different Soils in DR Congo

Stefan Hauser1*, TZ Bakelana2, D Bungu3, M Mwangu4

1International Institute of Tropical Agriculture, DR Congo, Avenue Haut Congo 4163, Gombe, Kinshasa

2Institut National pour l’Etude et la Recherche Agronomiques, Mvuazi, Province Kongo Central, DR Congo

3 University of Kinshasa, DR Congo

4Institut National pour l’Etude et la Recherche Agronomiques, Kiyaka, Province Kwilu, DR Congo

Received Date: May 12, 2020; Accepted Date: May 21, 2020; Published Date: June 02, 2020

*Corresponding Author: Stefan Hauser, International Institute of Tropical Agriculture, DR Congo.

Current Address: IITA Headquarters, Oyo Road, Ibadan, Nigeria. Tel: +2348055982045, +491747965656; Email: s.hauser@cgiar.org

Citation: Hauser S, Bakelana TZ, Bungu D, Mwangu M (2020) Cassava Root Yield Losses Caused By Root Shape, Rot and Peeling and Cut-Off for Processing Of Four Cassava Varieties on Different Soils in DR Congo. Adv in Nutri and Food Scie: ANAFS-185.

Abstract

Cassava root yields are commonly reported as fresh or dry mass yet usually as raw roots, comprising the peel and root tips, which are not used in processing. No information could be found on the mass losses caused by unsuitable root sizes and shapes, cut-off and peeling. This study determined such losses and evaluated if they are related to the root shape, variety and soil texture. Trials where conducted in DR Congo on coarse textured sand (CTS) and on sandy clay loam (SCL), using 3 improved and 1 local variety. On CTS, root mass losses due to unsuitable root size were 6-8% (improved varieties) and 18% (local variety). Cut-off losses were 13% (improved varieties) and 14 % (local variety). Peeling losses were 21% for all varieties. On SCL, losses due to unsuitable root sizes were negligible. Cut-off losses were 5% (improved varieties) and 8% (local variety). Peeling losses were 18% (improved varieties) and 20% (local variety). Cassava roots were longer and had a lower diameter on CTS. Cut-off losses were higher on CTS due to larger portions of roots lignified between planting stake and storage root. Peeling losses decreased with increasing mean root diameter. The variation in mean root diameter explained up to 55% of the peeling losses. Secondary storage roots emerging from primary storage roots only occurred on CTS and increased peeling losses.

Overall, cassava root yields, calculated from raw uncut and unpeeled roots, overestimate the fresh pulp mass, available for consumption or processing by 36% (improved varieties) and 44% (local variety) on CTS and by 23% (improved varieties) and 38% (local variety) on SCL.

Keywords: Cassava Raw Root Yield; Edible Root Yield; Peeling; Root Shape

Introduction

Cassava is an important food and cash crop in Africa. It is grown on a wide range of soils of different textures. Farmers’ choice of land is often limited and thus cassava is grown on soils that may be suboptimal for storage root formation and harvesting. Cassava is perceived to produce well on most soils and even poor soils [1, 2]. However, there is little quantitative data on root yield response to soil physical properties. The few reports are focusing on the effects of tillage [3] and even less is known about the effects of soil texture on the size and shape of cassava storage roots. Cassava roots are highly perishable and require processing immediately after harvest [4]. Processing, irrespectively of the target product, starts with the removal of the top end and the tip of the storage roots, followed by peeling of the entire root. In small and medium processing enterprises, most of these steps are done manually and are rather time consuming. The peel does in some varieties come off relatively easily in others it is attached and needs to be cut off with a knife. Depending on the skills of the person peeling, losses will vary. Peeling and cutting off the ends of roots causes inevitable losses. No information on the proportion of cassava cut off losses could be found. Cassava peeling losses were estimated at 25 to 30% of the fresh root mass [5], much higher than reported by [6] at 5 – 15%. No other data of the proportion of peel on cassava roots was found. However, peel thickness appears to be highly heritable and has a low variability within a plant [7] thus it can be assumed that within a variety the cassava peel thickness is relatively constant. Peeling losses should be explained by the roots’ volume: surface ratio, which is strongly affected by root diameter and length. With increasing diameter relative losses should decrease, while with increasing root length losses should increase.

No information could be found on how bulking cassava root diameter and length respond to soil texture. In the Democratic Republic of Congo cassava is the main staple and grown in all provinces for both roots and leaves. Soils in a large part of the western lowlands of DR Congo (Province Kinshasa and Kwilu) are coarse sand soils, while the intensively used inland valleys of Kongo Central province are sandy clay loam soils.

Over the last decade a large number of new cassava varieties have been released in DR Congo to combat the cassava mosaic disease. However, the newly released varieties were not characterized for their agronomic and processing traits. No information could be found on the new varieties’ root shape and peel thickness and thus the response of cassava peel thickness to soil conditions is unknown. The thickness of the peel of different cassava varieties and its mass proportion may differ. However, within the same variety, the proportion of peel of a root would decrease with increasing root diameter and increase with increasing root length, assuming that the peel thickness does not change with the root diameter and length. Theoretically cassava with higher root diameter should thus have lower peeling losses than cassava with low diameter roots. Generally, there is no information available on the effects of agronomic measures such as tillage, fertilizer application, irrigation and weed control on root shape. Accordingly no information could be found about the root shape of recently released varieties and the associated losses when removing tops, tips and the peel before the transformation process.

In addition to the inevitable mass losses cassava produces roots that are deemed unsuitable for processing and consumption due to their size and shape. Farmers leave roots they consider too small on the field and similarly do they reject roots of odd shape, which would require relatively large efforts to peel for the amount of food they would provide. There is little information on the mass of such rejected roots and the literature fails largely to mention if such roots were considered or excluded from the yield data.

Cassava root yield is usually determined on the raw unpeeled roots and thus does not reflect the amount of root material that is going to be processed. As such, all current yield data are likely overestimations of the cassava root mass amounts actually available for food production. The latter, in addition to the variable water content, will bias comparisons of the productivity of different crops.

This study was conducted to determine (1) the quantity of roots rejected due to their size and shape, (2) the quantity of root mass lost in cutting off tops and tips and in peeling, (3) the effect of the root shape on cut off and peeling losses; (4) the effects of cassava variety and soil texture on these losses. These data provided conversion factors from raw root mass to root mass fit for processing and were used to estimate the actually available cassava root mass for consumption and processing in major African cassava producing countries.

Materials and Methods

Sites and Soil

Trials were conducted at the research station of the ‘Institut National pour l’Etude et la Recherche Agronomiques’ (INERA) Mvuazi (Province Kongo Central, S 05.45475, E 014.88877, 431m absl) and at the INERA station at Kiyaka (Province Kwilu, S5.14193, E19.04475 at 597 m absl). The soil at Mvuazi is an alluvial sandy clay loam (SCL), while the soil at Kiyaka is a coarse textured sand (CTS). Soil was sampled with a 20mm auger at 0-10 and 10-20 cm depth. Soil was dried at 60°C to constant mass, passed through a 2 mm sieve and analyzed at the IITA laboratory at Yaoundé, Cameroon. Selected chemical properties and the particle size distribution are in (Table 1).

| Site | Mvuazi | Kiyaka | ||

| Depth (cm) | 0-10 | 10-20 | 0-10 | 10-20 |

| pH in water | 5.47 | 5.21 | 4.75 | 4.48 |

| org. C (g kg-1) | 21.7 | 14.1 | 6.2 | 5.4 |

| ttl. N (g kg-1) | 2.4 | 1.2 | 0.5 | 0.3 |

| avail. P (mg kg-1) | 12.46 | 9.03 | 20.57 | 5.66 |

| Ca (cmol[+] kg-1) | 8.56 | 2.74 | 1.15 | 0.22 |

| Mg (cmol[+] kg-1) | 1.54 | 0.77 | 0.29 | 0.04 |

| K (cmol[+] kg-1) | 0.22 | 0.11 | 0.29 | 0.03 |

| Sand (%) | 49.61 | 43.39 | 90.9 | 92.8 |

| Silt (%) | 27.11 | 27.26 | 3.7 | 2.4 |

| Clay (%) | 23.28 | 29.35 | 5.4 | 4.8 |

The trial at Mvuazi was planted during the last week of March 2008; the trial at Kiyaka was planted in the second week of April 2008. At Mvuazi the harvest was conducted from 1 to 5 April 2009, at Kiyaka from 21 to 26 April 2009.

Experimental Design

The trials were randomized complete block designs with 16 net plants per plot, planted on a 1 by 1 m square pattern. The improved cassava varieties Butamu, RAV and Mvuama were compared with an old variety Ngamanza. Treatments were repeated 4 times in each site. The varieties’ main traits are in (Table 2).

| Variety | Branching Height | Branching Intensity | Flowering Time | Flowering Intensity | Root pulp Color | CMD tolerance |

| Butamu | Very low | Very high | Very early | Very high | Yellow | Very high |

| Mvuama | High | Low | Very late | Low | White | Low |

| RAV | Medium | High | Very early | Extremely high | White | Medium |

| Ngamanza | Medium | Medium | Early | High | White | Very low |

Harvesting, Categorizing and Processing of the Roots

The harvesting and processing of the roots was supervised by researchers and conducted by INERA staff and collaborating farmers. This was to ensure that all roots were recovered from the soil without breaking. All roots, irrespective of size, shape and quality were taken to a weighing station. The classification of roots by shape, size and quality was done by a team of local cassava farmers and researchers, considering the usual local practice of accepting or rejecting roots for processing or consumption. The cutting off and peeling was done by local women, professionally processing cassava for home consumption and commercial purposes.

All 16 plants per plot were harvested and roots were separated carefully from the planting stake to prevent breakage. The roots of each plant were kept together, yet separate from the roots of other plants. Roots were washed to remove attached soil and the surface was dried. The roots were categorized into well shaped roots considered suitable for processing and consumption versus small primary, crooked, pearl-stringed, secondary and rotten roots that were rejected for processing and consumption. Root numbers and root fresh mass per category were recorded. Well shaped roots were those of a smooth surface and a tapered shape. The following roots were rejected because farmers would normally not carry them from the field to the homestead for processing, thus were complete losses: small primary roots emerging from the planting stake but deemed too small; crooked roots, which were bend such that peeling them required to cut them into sections and requiring more time to peel than similarly sized straight roots; pearl-stringed roots of abruptly changing diameter creating a series of large diameter root sections along the root axis interrupted by low diameter sections (<10 mm diameter); small secondary storage roots, emerging from a primary storage root but too small to peel them; rotten roots, those with discoloration of the pulp considered not fit for processing or consumption by the processing staff.

Assessing Mass Losses Caused By Rot, Small Size and Deformation

Obviously rotten roots were weighed and discarded. Some roots were identified as affected by rot during cut off and peeling, these were cut to the useful part and weighed again to obtain the correct useful mass; the rotten part was as well weighed. Primary roots deemed too small to peel and process were weighed and discarded. Crooked roots were broken up into pieces that could be peeled and processed if deemed large enough. Pieces deemed too small for processing were weighed and discarded. The same procedure was used to determine if pearl-stringed and secondary roots were useful or rejected. Due to the retention of root parts for processing and other parts of the same root being discarded some error in counting roots by category was introduced. However, the number of roots that were partially retained was negligible.

Assessing the Root Shape

The length of each root was measured, recorded and the length divided by 5. This produced the distance from the top to the point at which the root diameter was measured. From the point of the first diameter measurement the procedure was repeated three times along the root thus resulting in 4 diameter measurements at equal distances. Each diameter was recorded and the average of the 4 measurements calculated and used in the analyses as ‘mean root diameter’.

Assessing Cut Off and Peeling Mass Losses

Every root was weighed after washing and drying and the fresh mass recorded. Thereafter the root’s end connected to the planting stake (the top) was cut off such that only root matter fit for processing was retained. In some varieties the roots had started lignifying from the top and such material is unsuitable for processing, it can as well not be cut off with a knife. The person cutting off thus tried from the top end until cutting with a knife was possible. The end of the root (the tip) was cut off at the point where the root diameter became smaller than about 2.0 to 1.5 cm. After top and tip had been cut off, the root was weighed again and the mass recorded. Each root was then peeled by an experienced person to keep the losses at a minimum and was then weighed without peel. The peel was discarded. During the peeling the final decision if a root was fit for processing was made (mainly controlling for rot).

Mass Loss Calculations and Statistical Analysis

The root mass losses were calculated in a hierarchical order: the losses caused by small, deformed and rotten roots were calculated on the total raw root mass. The cut-off losses were calculated on the mass of marketable roots. The peeling losses were calculated on the marketable roots after top and tip removal. Thus individual loss percentages cannot be added to get total losses. Total root mass losses were calculated separately on the total raw root mass.

All data were analyzed using SAS v 9.2. Means were separated by proc GLM and pair-wise comparison (p diff). Proportions were arcus-sinus transformed before analysis. However, the data are presented as proportions. Simple correlations and regressions were conducted with proc CORR and proc REG to obtain correlation coefficients and the equations. The mass loss proportions are expressed as negative values. For the correlations between root shape parameters and the proportions of the cut off and peeling losses an outlier test was conducted using the interquartile range method and multiplying the interquartile range value with the factor 2. This caused the removal of 2.6 to 4.2% of the cut-off loss proportion data and of 1.9 to 2.3% of the peel loss proportion data.

Results

Distribution of Number of Roots by Shape, Size and Quality

The total number of evaluated roots was 3388 with more roots produced by all varieties at Kiyaka than at Mvuazi (Table 3). Variety Ngamanza was severely infested with cassava mosaic disease (CMD) at Mvuazi and suffered dieback of the majority of plants. Storage roots were produced by only 7 plants in one replication; thus it was not included in all analyses. At Kiyaka the CMD infestation of Ngamanza was less pronounced and storage roots were produced in all replications. The improved variety RAV produced fewer roots than varieties Mvuama and Butamu. Secondary storage roots emerging from an older, primary storage root were only found at Kiyaka, yet not at Mvuazi.

| Site | RAV | Butamu | Mvuama | Ngamanza | Total |

| Kiyaka | 532 | 626 | 685 | 361 | 2204 |

| Mvuazi | 372 | 449 | 335 | 28 | 1184 |

| Total | 904 | 1075 | 1020 | 389 | 3388 |

The proportion of roots considered useful for consumption or processing was 83.71% at Mvuazi and 63.15% at Kiyaka (p<0.0001). Of the roots deemed useless the largest portion was due to an insufficient size of primary storage roots followed by secondary storage roots (Table 4). Of all rejected roots these two categories contributed 96.9% at Mvuazi and 97.6% at Kiyaka. Crooked roots were more frequent at Mvuazi (2.9% of rejected roots) and pearl-stringed roots were more frequent at Kiyaka (1.6% of rejected roots). Root rot caused the smallest proportion of roots being rejected in both sites.

| Mvuazi | Kiyaka | p diff | |

| Useless total | 16.29 | 36.85 | <0.0001 |

| Primary small | 15.78 | 20.66 | ns |

| Secondary small | 0.00 | 15.30 | <0.0001 |

| Pearl-stringed | 0.02 | 0.60 | 0.0211 |

| Crooked | 0.48 | 0.18 | ns |

| Rotten | 0.01 | 0.10 | ns |

The improved varieties did not differ in the proportions of useful roots (80.8%), while Ngamanza produced with 45.2% a significantly lower proportion of useful roots. The different categories of rejected roots were not different between varieties except for the pearl-stringed roots which were significantly more frequent in variety RAV than all others (0.89% versus 0.16%, p<0.0302).

Root Mass Losses Due To Shape, Size and Quality

The combined root mass loss proportion from all rejected roots was affected by site and variety. Losses were 10.8% of the total root mass at Kiyaka and 4.5% at Mvuazi (p< 0.0001). At Kiyaka the mass loss through rejected roots was 3.68% by too small secondary storage roots, 2.9% by too small primary storage roots, 2.32% by crooked roots, 1.91% by pearl-stringed roots and 0.06% due to root rot. At Mvuazi crooked roots contributed 3.46% to the mass loss, pearl-stringed roots 1.1%, rotten roots 0.52% and too small primary storage roots 0.48%.

The improved varieties did not differ in mass loss from rejected roots (3.97%), while Ngamanza lost 17.1% of root mass (p<0.0001).

Root Mass Losses Due To Cut-Off and Peeling

Across the sites the average mass loss from cutting tops and tips of roots was 10.2% and was higher at Kiyaka with 14.3% than at Mvuazi (6.1%, p<0.0001). Varieties did not differ.

The average mass loss from peeling was 19.4% and did not differ between sites, although a numerically lower loss was recorded at Mvuazi (19.0%) compared with Kiyaka (19.8%, p<0.0958). Variety Ngamanza lost 21.2% fresh mass through peeling, significantly more than the improved varieties (average 18.8%, p<0.0239), without differences between the improved varieties.

The total cut-off and peeling fresh mass loss was higher at Kiyaka (38.1%) than at Mvuazi (27.3%, p<0.0001). Variety Ngamanza lost in total 41.9% of the root mass, while the improved varieties lost on average 29.6% (p<0.0001).

Root Diameter and Root Length

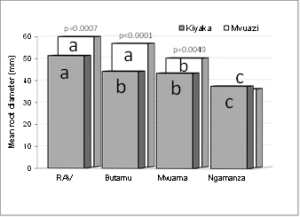

The mean diameter of the roots was affected by the site and there was a significant site × variety interaction. At Kiyaka the roots had a mean diameter of 44.1 mm; at Mvuazi 50.6 mm (p<0.0001). Variety RAV produced the highest diameter roots (Figure 1), Ngamanza the smallest. The improved varieties had significantly lower mean roots diameters at Kiyaka than at Mvuazi, yet no such difference was found in Ngamanza.

Figure 1: Mean cassava root diameter of four varieties at two sites in DR Congo. Within site, columns labelled with the same letter are not significantly different. P values above columns of the same variety indicate the level of significance between sites.

Roots were significantly longer at Kiyaka (37.5 cm) than at Mvuazi (25.8 cm; p<0.0001). Variety Ngamanza produced the longest roots at Kiyaka, yet the shortest at Mvuazi (Figure 2). Only at Kiyaka were differences between varieties significant.

Figure 2: Mean cassava root length of four varieties at two sites in DR Congo. Within site, columns labelled with the same letter are not significantly different. P values above columns of the same variety indicate the level of significance between sites.

Mean root length and mean root diameter were significantly negatively correlated with the linear regression:

root diameter = -0.7725 root length + 74.5 (adjusted r2=0.597; p<0.0001) and a power function:

root diameter = 369 root length-0.587 (adjusted r2=0.6675; p<0.0001).

Relationships between Root Diameter, Root Length and Cut-Off and Peeling Losses

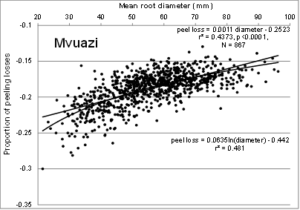

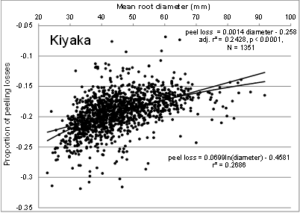

Correlations between root length and mean root diameter and the proportion of peeling and cut-off losses were weak. At Mvuazi, peeling and cut-off losses decreased with increasing root length and mean root diameter (Table 5). At Kiyaka the proportion of cut-off losses increased with increasing root length and mean root diameter. The proportion of peeling losses had no response to the root length at Kiyaka and the proportion of peeling losses decreased with increasing mean root diameter. Across the varieties the closest correlations were those between mean root diameter and the proportion of peeling losses in both sites with r2 = 0.2861 at Mvuazi and r2 = 0.1467 at Kiyaka (Figure 3). These regressions were slightly improved when a logarithmic equation was used.

| Kiyaka | Mvuazi | ||||

| Losses caused by | Cutting | Peeling | Cutting | Peeling | |

| Root

length |

r2 | (-) 0.0756 | 0.0018 | 0.0763 | 0.0046 |

| p | <0.0001 | ns | <0.0001 | 0.0250 | |

| Mean root

diameter |

r2 | (-) 0.0025 | 0.1495 | 0.0708 | 0.2861 |

| p | ns | <0.0001 | <0.0001 | <0.0001 | |

| Note: (-) denotes a negative relationship, i.e. losses increased with increasing length or diameter. r2 values in bold are significant at p<0.05. | |||||

Table 5: Coefficients of determination (r2) and p values for the correlation of root length and root diameter with cut off and peeling losses.

Figure 3: Relationship between the mean root diameter and the proportion of peeling losses at Kiyaka and Mvuazi across all cassava varieties.

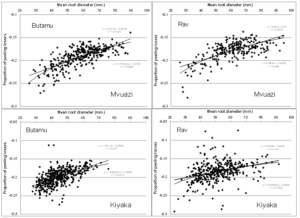

Within sites there were differences between varieties in the response of the proportion of peeling losses to the mean root diameter (Table 6). Correlations were generally closer at Mvuazi than at Kiyaka. (Figure 4) shows for the varieties Butamu and RAV the relationships at Mvuazi and Kiyaka. In variety Butamu the linear correlation is good in both sites and transformation to a logarithmic scale improves the fit only marginally. For variety RAV the linear correlation at Kiyaka is rather poor, while at Mvuazi it is good and was improved by a relatively large margin (0.07) when transformed to a logarithmic scale.

| Kiyaka | Mvuazi | |||||

| Variety | r2 | N | p | r2 | N | p |

| RAV | 0.1142 | 354 | <0.0001 | 0.4218 | 229 | <0.0001 |

| Butamu | 0.3254 | 412 | <0.0001 | 0.5112 | 316 | <0.0001 |

| Mvuama | 0.2651 | 418 | <0.0001 | 0.4295 | 322 | <0.0001 |

| Ngamanza | 0.3168 | 167 | <0.0001 | na | ||

Figure 4: Correlations between the mean root diameter and the proportion of peeling losses at Mvuazi (upper graphs) and Kiyaka (lower graphs) for the varieties Butamu (left) and Rav (right).

Discussion

Although high cassava root yields are desired by farmers, the need to peel before processing leads to a preference for certain root sizes termed “the larger the better” by [8]. This study shows that a considerable number of cassava roots are too small or misshaped and therefore not used for processing and consumption. Although on the CTS soil the proportion of unsuitable misshaped roots was rather high, this did not translate into similarly high root mass losses because a majority of roots deemed useless was categorized as too small, thus had low mass, and those which were misshaped (crooked or pearl-stringed) were not in all cases a complete loss but were partially still useful. Important is that the largest portion of roots deemed useless was due to their small size and that misshaped and rotten roots were relatively few. This study cannot identify reasons for the crop to form small roots, yet the fact that only on the CTS soil secondary storage roots were formed may point at the possibility that soil texture, potentially mediating changes in water supply, specifically short before the harvest, may cause new root formation when rains commence after a longer dry phase. Such roots, initiated late, would still be small at harvest. Rapid changes in soil moisture would be more pronounced on the CTS soil than on the SCL soil, where such secondary storage roots were not observed. The higher proportion of pearl-stringed roots on the CTS soil may be caused by the same process, yet such that a root that started bulking stopped expanding due to dry conditions and later recommenced, yet not in the same place but further along the root thus forming a second bulking site on the same axis. Crooked roots are likely caused by physical impediments to root growth and bulking, which may be more frequently found on heavier SCL soils. The higher proportion of crooked roots on the SCL soil would corroborate this. Thus soil texture affects the proportion of roots unsuitable for processing and consumption, such that more unsuitable roots are found in coarse textured sand soil.

This study reveals that the soil texture has an effect on the root shape of cassava and the associated mass losses caused by unsuitably shaped roots and tip and top cutting-off and peeling. However, the soil chemical properties of the sandy clay loam at Mvuazi were better than those of the sand soil at Kiyaka, except for the P and K content in the 0-10 cm layer. In so far the soil texture was confounded with the chemical properties. There is no information in the literature on the effects of soil chemical properties on the root shape of cassava. However, the fresh raw root yield (not reported here) was higher at Kiyaka despite the less favourable soil chemical properties. This may indicate that the soil chemistry was not as important for the growth and biomass production, than other factors not considered here. The dry season is about 2 months at Kiyaka compared with 4 months at Mvuazi. It is likely that the longer rainy phase promoted cassava growth and yield strongly at Kiyaka despite the poorer soil.

Roots on the CTS soil were of lower diameter, yet longer than those grown in the SCL soil. It is not possible to differentiate if shorter roots in the SCL soil were caused by the soil physically restricting length growth of the bulking root portion or if the amount of assimilates to form storage roots was limiting length. It would have been expected that on the CTS soil the expansion of bulking roots in any direction is less impeded by the soil as the aggregation of the sand soil would be poor. Apparently the SCL soil did not restrict radial expansion of bulking roots, yet it is not clear why the roots did not attain larger diameters on the CTS soil.

The cut-off losses were not related to the root diameter at Kiyaka and were weakly positively related at Mvuazi (r2=0.0708), thus were not or very poorly affected by the root shape. This is an expected result. Cut-off losses were negatively correlated with root length at Kiyaka, yet positively correlated at Mvuazi. In both sites the r2 were around 0.076, thus the correlations were rather weak and may be considered irrelevant. The negative correlation at Kiyaka (meaning that losses increased with increasing root length [losses expressed as negative proportions]) may be related to the fact that some larger and longer roots had lignified top ends towards the planting stake. These lignified portions, measured from a few to a maximum of ~20 cm lengths, and had to be cut-off because they are not suitable. The lignification may be root age related such that older roots have a stronger tendency to lignify and they are as well likely to grow longer. Thus with increasing age and length of the roots this proportion would get larger and may have contributed to increased cut-off losses with increasing root length. However, it remains to be investigated why on the SCL soil roots did not lignify at the top although they were of the same age.

Peeling losses on 7 cassava varieties ranged between 17.5 and 26.8% of the fresh matter [9], with significant differences between varieties. Variety RAV had the lowest losses with 17.5%. However, other losses such as cut off and misshaped roots were not considered.

The peeling losses were not correlated with the root length at Kiyaka and very weakly at Mvuazi (r2=0.0046) which should be considered irrelevant. Thus root length had no effect on the proportion of mass loss due to peeling. Although not absolute evidence, this may indicate that the peel thickness does not change along the bulking root within a variety.

Peeling losses were well correlated with the mean root diameter in both sites, yet this relationship was twice as close at Mvuazi than at Kiyaka. Decreasing peeling losses would be expected with increasing root diameter due to the changes in the volume:surface ratio and this study provides evidence that this is the case. However, the relatively low r2 of this relationship in all varieties at Kiyaka compared with those at Mvuazi is difficult to explain. One reason may be the large proportion of primary storage roots from which secondary storage roots emerged at Kiyaka. Primary storage roots are usually of a lower diameter in the places where secondary storage roots emergence, i.e. they cause a constriction around the primary root. This will lead to difficulties peeling which usually causes more root material being cut off to get all peel out of the constricted area. Thus roots with such constrictions would have relatively higher peeling losses and thus contribute to weaker correlations. At Mvuazi no secondary storage roots were observed.

The results of this study indicate that cassava varieties should produce few, high diameter roots to keep cut-off and peeling losses at a minimum. The losses caused through lignified root tops appear to be site dependent. The generally higher cut-off and peeling losses as well as the higher proportion of mass lost through misshaped roots on the CTS soil clearly indicate that sandy clay loams are more suitable for low loss cassava production. However, farmers may not have the choice of land with ideal texture and need to consider the pragmatic aspects of cassava production and harvest with the attached labour requirements. They thus would need information on the varietal differences in root size, shape and related losses. Although here the soil conditions affected the root shape, improvements may be possible through breeding for varieties with high root diameter.

Consequences for Yield Assessments and Production Statistics

Although production statistics do not provide data on root diameters the mean proportion of fresh mass losses encountered between the harvest of the raw roots and the root pulp ready to enter processing or consumption can be estimated on a larger scale. Assuming a best case scenario of losses in the region being equal to those determined for the improved varieties of 23 % on sandy clay loam and 36% on the coarse textured sand soil the amounts of fresh edible cassava root pulp produced would need to be reduced as shown in (Table 7). To validly compare crops such as cassava, sweet potato, yam, banana and plantain, the fresh mass of the edible portion needs to be determined. Reporting yields as fresh raw material such as complete banana or plantain bunches leads to strongly biased impressions of these crops’ productivity [10] and may lead to suboptimal decision making on the composition of crops in farms. More importantly such raw data based yield expressions may lead to policies that might favour crops of a lower productivity. The Guardian [11] reported on 28 March 2013 FAO statistics on cassava and maize production in Africa, quoting 140 million metric tons of cassava versus 65 million metric tons of maize grain. Maize grain may need to be cleaned but there are no major mass losses to be expected. Cassava however, will have cut-off losses and needs to be peeled before it enters the processing or consumption. If the here determined average losses (29.5%) are applied then the crop provided 98.7 million tons fresh edible root pulp, which contains variable amounts of water. Assuming 35% root dry matter content the crop produced 34.5 million tons edible root dry matter, a mere 25% of the figure reported. Adjusting the maize grain production figure by 18% moisture content and cleaning losses, the maize production was 53.3 million tons, thus on an edible dry matter basis 18.7 million tons more than cassava.

| Raw production in | Fresh mass of edible pulp | Estimated edible pulp dry matter* | |||

| Country | 2016 | SCL | CTS | SCL | CTS |

| Nigeria | 57,134,478 | 43,993,548 | 36,566,066 | 15,397,742 | 12,798,123 |

| Ghana | 17,798,217 | 13,704,627 | 11,390,859 | 4,796,619 | 3,986,801 |

| DR Congo | 14,677,809 | 11,301,913 | 9,393,798 | 3,955,670 | 3,287,829 |

| Tanzania | 5,575,304 | 4,292,984 | 3,568,195 | 1,502,544 | 1,248,868 |

| Cameroon | 5,501,749 | 4,236,347 | 3,521,119 | 1,482,721 | 1,232,392 |

| Benin | 4,317,642 | 3,324,584 | 2,763,291 | 1,163,605 | 967,152 |

| Cote d'Ivoire | 3,210,614 | 2,472,173 | 2,054,793 | 865,260 | 719,178 |

| Uganda | 2,885,446 | 2,221,793 | 1,846,685 | 777,628 | 646,340 |

| Congo | 1,365,698 | 1,051,587 | 874,047 | 368,056 | 305,916 |

| Central African Rep. | 714,042 | 549,812 | 456,987 | 192,434 | 159,945 |

| Kenya | 571,848 | 440,323 | 365,983 | 154,113 | 128,094 |

| Source of raw production data: FAOSTATS (2018). SCL = Sandy clay loam, CTS = Coarse textured sand | |||||

Conclusion

Fresh mass losses of cassava roots caused by misshaped roots and cut-off tops and tips and peeling range from 23% to 44% depending on variety and soil conditions. Such losses need to be considered when reporting and comparing crop yields. On light textured and chemically poorer soils such losses are higher than on richer and more fine-textured soils. The increase in peeling losses with smaller root diameters calls for the breeding programs to look for traits in cassava to form few large diameter roots.

Declaration on Competing Interests: The authors declare no competing interests.

Author contributions

Hauser designed the trials, developed the protocols, supervised root evaluations and conducted data analysis and wrote the manuscript. T.Z. Bakelana implemented and supervised trials at Mvuazi, participated in data collection and contributed to writing the manuscript. D. Bungu participated in data collection and contributed to writing the manuscript. M. Mwangu implemented and supervised trials at Kiyaka, participated in data collection and contributed to writing the manuscript.

References

- Aerni P (2005) Mobilizing Science and Technology for Development: The Case of the Cassava Biotechnology Network (CBN). Proceedings of the 9th ICABR International Conference on Agricultural Biotechnology: Ten years later.

- Spencer DSC, Ezedinma C (2017) Cassava cultivation in sub-Saharan Africa. In: Hershey C (editor) Achieving sustainable cultivation of cassava Vol 1: Cultivation techniques. 1-26.

- Byju G, Ravindran CS, Nair RR, Ravi V (2010) Tillage and planting methods on soil properties, yield, root rot and nutrient uptake in a continuously grown cassava field in a semi-arid Vertisol of India. Adv Hort Sci 24:176-182.

- Iyer S, Mattinson DS, Fellmann JK (2010) Study of the early events leading to cassava root postharvest deterioration. Tropical Plant Biol 3:151-165.

- FAO (2001) Proceedings of the Validation Forum on the Global Cassava Development Strategy. Food and Agriculture Organization of the United Nations International Fund for Agricultural Development Rome, 2001.

- Udo J (2018) Did You Know …That You Can Make Millions From Cassava Peels? Biz Opportunity Newsletter, June 22.

- Pérez JC, Lenis JI, Calle F, Morante N, Sánchez T et al., (2011) Genetic variability of root peel thickness and its influence in extractable starch from cassava (Manihot esculenta Crantz) roots. Plant Breeding 130:688-693.

- Nweke FI, Lutete D, Dixon AGO, Ugwu BO, Ajobo O et al., (2000) Cassava production and processing in the Democratic Republic of Congo. Collaborative Study on Cassava in Africa (COSCA) Working Paper No. 22. 203-206.

- Mahungu NM, Kalemba J, Nluta S, Nuambote O, Bidiaka S (2016) the influence of cassava root peels in economic dry root yield estimates. Poster presented at the World Congress on Root and Tuber crops, Nanning Guangxi, China 18-23 January 2016.

- Hauser S, Van Asten P (2010) Methodological considerations on banana (Musa spp.) yield determinations. Acta Horticulturae 879:433-444.

- Van Vark C (2013) Cassava can become Africa's new cash crop. The Guardian 28 March 2013.