Publication Information

Frequency: Continuous

Format: PDF and HTML

Versions: Online (Open Access)

Year first Published: 2019

Language: English

| Journal Menu |

| Editorial Board |

| Reviewer Board |

| Articles |

| Open Access |

| Special Issue Proposals |

| Guidelines for Authors |

| Guidelines for Editors |

| Guidelines for Reviewers |

| Membership |

| Fee and Guidelines |

|

Balanites aegyptiaca: A Multipurpose Tree Species for Forest Based Industry Development in Sudan

Hanadi Mohamed Shawgi Gamal¹*, Majdaldin Rahamtallah Abualgasim², Haytham Hashim Gibreel3, Ashraf Mohamed Ahmed Abdalla¹, Kamal Fadl Elseed Elkhalifa Mohammed3

¹University of Khartoum, Faculty of Forestry, Department of Forest Products and Industries, Khartoum, Sudan

²Environmental, Natural Resources and Desertification Research Institute, National Centre for Research, Khartoum, Sudan

3University of Khartoum, Faculty of Forestry, Department of Forest, Silviculture, Khartoum, Sudan

Received date: October 24, 2020; Accepted Date: November 02, 2020; Published Date: November 11, 2020;

*Corresponding author: Hanadi Mohamed Shawgi Gamal, Department of Forest Products and Industries, University of Khartoum, Sudan. Tel: 00249114699181; Email: hanadishawgi1979@yahoo.com

Citation: Gamal HMS, Abualgasim MR, Gibreel HH, Abdalla AMA, Mohammed KFEE (2020) Balanites aegyptiaca: A Multipurpose Tree Species for Forest Based Industry Development in Sudan. Adv in Agri, Horti and Ento: AAHE-134.

Abstract

Sudan is endowed by a great diversity of tree species, nevertheless the utilization of wood resources has traditionally concentrated to a few number of species. Most of the indigenous hardwood tree species in Sudan are used as charcoal, firewood and fuel wood due to the lake information about their wood properties. Despite the richness of Sudan in most of basic factors required to establish forest based industries it still almost entirely dependent on imports to satisfy its needs of the products of such industries like pulp and paper, fiberboard,…etc. There is an urgent need to evaluate the available locally raw materials as potential sources for forest based industries. This would not only reduce imports, but it would also provide an economic incentive to the forestry and industrial sectors of Sudan. The present study was carried out to investigate some wood properties of Balanites aegyptiaca and to assess its suitability for pulp and paper and flooring industries. The wood materials were collected from four states in Sudan. Some anatomical, physical and mechanical properties were investigated and their results were used to consider the suitability of the selected tree species for pulp and paper and flooring industries. In anatomical investigations, fiber length, diameter, lumen diameter as well as double wall thickness were measured from which the Runkel ratio, slenderness ratio and coefficient of Suppleness (or flexibility coefficient) were obtained. Concerning physical and mechanical investigations, wood density and hardness strength were determined respectively. The results revealed that the wood anatomical, mechanical and physical properties of the study species may qualify it for pulp and paper and flooring industries. The results of this study could enhance the establishment of such forest based industry in Sudan.

Keywords: Balanites Aegyptiaca; Development; Forests Based Industries; Sudan

Introduction

Sudan is a country rich in forest including a large number of tree species; it encompasses about 3156 species belonging to 1137 genera and 170 families (Broun and Massay 1929, Andrews, 1950, 1952, 1956, and El Amin 1990). Nevertheless the utilization of wood resources has traditionally concentrated to a few numbers of species, due to the lack of information about the wood properties of many indigenous species growing in Sudan. Despite the richness of Sudan in most of the basic factors required to establish pulp and paper and flooring industry, it is still dependent on import to satisfy its needs for pulp and paper. There is currently no flooring industry in Sudan. It is therefore evident that there is an urgent need to assess the suitability of local fibrous raw materials for paper and flooring industries. Domestic sources of such industries would not only reduce imports but also provide an economic incentive to the forestry and industrial sectors of Sudan.

Wood density is the most significant property in determining wood end uses. It is strongly effect on the yield, strength, and general quality of most of the products produced from wood.

It is considered the best single index for pulp yield and quality (Bendtsen 1978). Wood anatomy is described as fundamental basis of timber utilization. A wood anatomist can suggest uses, especially for woods that are not in a commercial demand. Previous studies have shown that fiber morphology is an important indicator for end-use. For instance, the fibers dimension and their derived values correlates with most of the strength properties of pulp. Sadiku and Abdukareem (2019) have successfully used the fiber dimension and their derived values to assess the suitability of some nigerian tropical timber species for pulp and paper making. Ajuziogu and Ojua (2020) in their Study on the wood and bast fibres of Gmelina arborea have used the fiber morphology to assess the suitability of their studied species bark and wood for pulp and paper making. While, Ajala and Noah (2019) have used the fiber dimension and their derived values of Aningeria Robusta wood to assess its suitability for paper making. Many Other researchers like Saikia et al. (1997), Ogbonnaya et al. (1997), Ververis et al. (2004), Ajuziogu et al. (2010), and Ekhuemelo and Tor (2013) have also successfully used the fibers dimension and their derived values to assess the suitability of various fiber raw materials for pulp and paper manufacture. According to Haygreen and Bowyer (1996), mechanical properties are usually the most important characteristics of wood product to be used in structural applications such as flooring and rafters, structural panel roof, wall sheathing, etc…

Wood properties studies have a special significance in countries like Sudan where only a few timbers are well known. After the oil extract in Sudan, great amounts of wood will be available for uses other than energy because oil will gradually replace wood, the main energy resource. This research is an attempt to provide basic information on some anatomical, mechanical and physical properties of Balanities aegyptiaca wood in order to assess its suitability for pulp and paper and flooring industries. Balanites aegyptiaca is a common wild tree belonging to the family Balanitaceae. It is an evergreen, multi-branched and armed tree species, that varies in height from 8 to 10 m (El Amin 1990) or 15 m and in diameter from 30 to 50 cm (Thirakul 1984). The wood makes excellent firewood and good quality charcoal (Thirakul 1984); it is also used for local furniture and agricultural implements. The fruit is edible and is used against constipation and as anti-diabetic. The sapogenin, yamogenin, and diosogenin, can be extracted from all parts of the plant (Vogt 1995). The general feature of Balanities aegyptiaca tree species is illustrated in (Figure 1).

Figure 1: Balanites aegyptiaca general features. 1. Adult tree; 2. Fissured bark; 3. Leaves and flowers; 4. Green immature fruit and yellow mature fruit, the photo shows also the thorns; 5. Wood, (cross section showing the fluted stem).

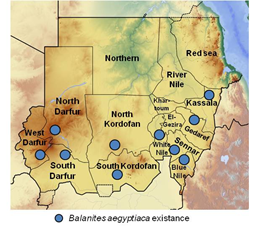

Balanities aegyptiaca tree species is an indigenous species in Sudan with a wide range of natural occurrence over diverse climatic and edaphic conditions (Suliman and Jackson 1959). It grows in sand, clay, cracking clay and gravel soils (Suliman and Jackson 1959 and Orwa et al. 2009). So, the tree is widely distributed in the Sudan (see Figure 2).

(Adapted by the author from Source1).

Figure 2: Balanites aegyptiaca distribution in Sudan.

Materials and Methods

Materials

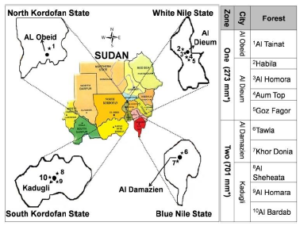

The wood raw materials were collected randomly from 10 forests located in four states in Sudan namely: North Kordofan State, South Kordofan State, Blues Nile State and White Nile State. According to the mean annual rainfall for ten years (2000-2009), the study areas were divided into two zones; zone one: with a relatively low rainfall (273mm annually, mean average rainfall), and zone two: with relatively high rainfall (the mean average rainfall is 701 mm annually).

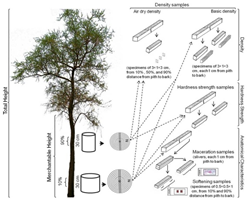

The location and characterization of the study areas are summarised in (Figure 3), while sampling procedure is presented in (Figure 4).

Three healthy and straight trees were selected randomly and cut down from each forest give a total of 30 trees. The tree total height, merchantable height and diameter at breast height (DBH) were measured for each tree. Two discs of 10 cm thick were obtained from each tree at 10% and 90% of the merchantable height. Afterwards the discs were cut into small samples or strips include tree’s pith) with 3 x 3 x tree diameter in cm. Two free of defect strips were taken from each 90% disc and three from 10% disc given a total of 5 strips for

(*= Zone’s mean annual rainfall of 10 years (2000-2009).

Figure 3: Location and characterization of the study areas.

(include tree’s pith) with 3 x 3 x tree diameter in cm. Two free of defect strips were taken from each 90% disc and three from 10% disc given a total of 5 strips for each tree. Then each strip was cut into small samples and used for wood properties investigations (for more details see Figure 4).

Figure 4: Sampling procedure.

Methods

Wood density

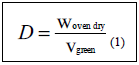

Two wood density types were measured in the current study: basic density as well as air dry density. The wood basic density was measured as oven-dry mass/green volume. One wet sample (strip) from each stem height (10% and 90%) was taken and was cut from the pith (center) into two parts and each part has been sawn into small specimens of 3×1×3 cm. The specimens green volume was determined by water replacement method. Then were immediately transferred into an oven and dried for 48-72 hours until the constant mass was attained. The dry weight was measured using sensitive digital balance. The basic density was calculated using the following formula:

Where, D is the basic density in kg/m³. Woven dry is the dry weight in kilogram. Vgreen is the green volume in m³.

Where, D is the basic density in kg/m³. Woven dry is the dry weight in kilogram. Vgreen is the green volume in m³.

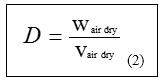

The wood air dry density was measured as air dry mass/air dry volume. One sample was chosen from each height (10 % and 90%). The samples were then cut from the pith (centre) into two parts (radiuses). One radius was chosen for air dry density determination. Small specimens of 3×1×3 cm were cut from each radius. The air dry gravimetric method was conducted on the basic of DIN 52 182 (Anonymous 1991) the samples were conditioned to a constant mass at 20 ᵒC air temperature and 65 % relative humidity. The specimen’s weight was measured using a sensitive digital balance. The volume was measured using micro callipers (Mitutoyo Digimatic Model CDN-P30).The basic density was calculated using the following formula:

Where, D is the air dry density in g/cm³. Woven dry is the dry weight in g. Vgreen is the green volume in cm³.

Fiber dimensions and their derived values:

Two anatomical tests were conducted, maceration test to measure fiber length, and the softening test to measure fiber diameter and lumen diameter. One air dry sample or strip from stem height 10% was selected from each tree of the study species and was separated from the pith localization into two samples (radiuses). One radius was taken to perform the anatomical properties investigations as illustrated in (Figure 4).

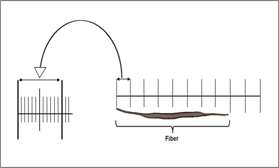

The maceration procedure developed by Shultze as cited in Jane (1970) was adopted to macerate the woody materials. Small slivers of wood were placed in test-tubes, to which 65% nitric acid with a few crystals of potassium chlorate (KCLO3) was added and then warmed up in a water bath for about 5-10 minutes. The macerated material is washed, stained, rewashed, fixed in slides and then left left 24 hours to dry. A number of 40 fibers length were measured randomly from each sample using light microscope (model: Variant Jenamed) with an 10x ocular lens provided with a measuring scale graduated into ten equal segments and each segment is graduated into ten sub-segments (Figure 5).

Figure 5: Fibre length measurement using measuring scale.

Concerning the softening test, One sample of 0.5 x 0.5 x 1 cm was cut from each sampling point (10% and 90% distance from pith to bark).The samples were softened by boiling in water for about 8-10 hours. Transverse (cross) sections 10-15μm in thickness were cut using GSL1 microtome (invented by H. Gaertner, F.H. Schweingruber& S. Luccinetti). The prepared sections were dehydrated in a graded ethanol series (25%, 50% and absolute, respectively), stained and dehydrated again. The sections were fixed in slides and left 24 hours to dry.

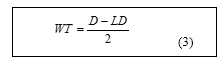

Nikon coolpix 990 Camera fixed in light microscope (model: Variant Jenamed) which in turn was connected with PC were used to take photos from the prepared slides. The image j software was used to measure the fibers’s dimension from the photos. A number of 40 fibers were selected randomly to measure fiber diameter and lumen diameter (Figure 6). Fibers wall thickness was calculated using the following equation:

Where: WT is wall thickness; D is diameter and LD is lumen diameter.

Three derived values were also calculated using fiber dimensions:

- Slenderness ratio as fiber length/fiber diameter,

- Flexibility coefficient as (fiber lumen diameter/ fiber diameter) × 100 and

- Runkel ratio as (2 × fiber cell wall thickness)/lumen diameter.

Figure 6: Fibres diameter and lumen diameter measurements using ImageJ software.

Hardness strength

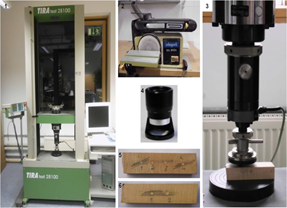

Brinell hardness test was conducted on the basic of DIN EN 1534 to measure the hardness strength of the studied species. One conditioned at 12% sample (stripe) from each stem height (10% and 90%) were selected. Each stripe was split from the pith (center) into two radiuses. In order to obtain soft surface, the four sides of each radius were sanded using sanding machine. The TIRA test 28100 machine provided by a hardened steel ball with a diameter of 10 ± 0.01 mm was used to perform the hardness test in the transverse and radial sections.

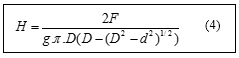

The following equation has been used to get the hardness:

Where:

H is the hardness,

g is the acceleration due to gravity, in meters per second squared,

π is the factor „pi“ (≈ 3.14),

F is the nominal force in Newton,

D the ball diameter in millimetres,

d is the diameter of the impression point in millimetres.

Results and Discussion

The Suitability for Pulp and Paper Making

(Table 1) shows the mean values for the investigated fiber characteristics as well as wood basic density of the study species compared with the acceptable values for Pulp and paper making (PPM) and those of Gmelina arborea which is used commercially used in pulp and paper making in the world.

Figure 7: Hardness test methodology: 1.TIRA test 28100, 2.Sandermachine, 3.Press of the steel ball into wood sample, 4. Micro loupe, 5. and 6. Indentation point in cross and radial sections, respectively.

Property

Balanites aegyptiaca

Acceptable values for PPM

6Gmelina arborea

Basic density (kg/m³)

660

350-6501

510

Fibre length (mm)

1.15

≥ 12

1.28

Flexibility Coefficient (%)

41

> 603

73

Runkel ratio

1.48

0.25-1.54

0.39

Slenderness ratio

88

>335

50

1Casey (1980), 2Source 2, 3Petri (1952), Okereke (1962), Rydholm (1965), 4Valkomer (1969), 5Xu et al. (2006) and 6Ogunkunle and Oladele (2008).

The average basic density of Balanites aegyptiaca (660kg/m³) was in the range of tropical hardwoods of 400-900 kg/m³ (Tissot 1985). It could be graded as medium according to Melo et al. (1990) classification. Khristova el al. (1997) found the wood basic density of Balanites aegyptiaca to be 619 kg/m³ which is more or less comparable with those obtained in the current study (660 kg/m³). Balanities aegyptiaca basic density is almost within the range for commercial temperate pulpwood of 350-650 kg/m³.

The fiber length of the study species is in the range of hardwood of 0.7-2.0 mm (Ilvessalo- Pfaffli 1995) and considered as short according to Wagenführ (1984), and Medium according to IAWA (1989) classifications. They are also comparable with the acceptable value for PPM. Many authors confirmed the suitability of species with equal and event shorter fiber length than the studied species for pulp and paper making. Good examples are the species studied by Khristova el al. (1997, 1998), Khristova and Karar (1999), Khristova el al. (2004) and that of Dutt and Tyagi (2011). The fibers were of good slenderness ratios (88), much more than the acceptable value for papermaking of < 33. It is much bigger than almost all those of hardwood using in papermaking and also bigger than some soft wood species like Pinus kesiya (56.51) as sited in Dutt and Tyagi (2011). This enhances their suitability for pulp and paper making.

The Runkel ratio of Balanites aegyptiaca estimated in the current study was 1.48 which is at the upper end of the acceptable range of papermaking (0.25-1.5) as sited by Valkomer (1969). Khristova el al. (1997, 1998) confirmed the suitability of species with higher Runkel ratio for papermaking (2.9-2.5 respectively). Nevertheless, the flexibility coefficient of the study species are much lower than the acceptable value for papermaking of preferably >60. But they are comparable to those of the species studied by other authors (Khristova el al. 1997, 1998 and Khristova and Karar 1999). In comparison with Gmelina arborea wood properties shown in (Table 1), the study species has comparable fibre length, lower flexibility coefficient, higher Runkel and slenderness ratios and higher wood density. Therefore, it is considered compatible for pulp and paper making. However, it is recommended to mix the pulp produced from the study species wood with soft-wood or recycled paper pulps to improve their properties.

The Suitability for Flooring Industry

In flooring industry, the most important wood properties which determine the suitability of the wood for such industry is the hardness. Wood density is acknowledged to affect most mechanical properties (Haygreen and Bowyer 1996, Barnett and Jeronimidis 2003, Bowyer et al. 2003, Kiaei and Samariha 2011). Therefore, this section assess the suitability of the study species for flooring industry by comparing their air dry density and Brinell hardness strength mean values by those of the Amercian´s flooring industry benchmark Red oak (Quercia rubra) and by those of Robinia pseudoacacia (which is widely used in flooring industry) as references species (Table 2).

property

Balanites aegyptiaca

References species*

Robinia pseudoacacia

Quercia rubra

Air dry density (g/cm³)

0.789

0.77

0.7

Hardness strength (N/mm2)

Transverse surface

87

78

53-66

Radial surface

46

34

29-36

*Wagenführ (2007)

Based on the Malaysian Grading Rules for Sawn Hardwood Timber (Anonymous 1984), Balanites aegyptiaca wood can be classified as medium (from 0.720 to 0.800 g/cm3). The study species wood can be classified as very hard, according to the Brinell hardness strength classifications provided by in Mörath in Lohmann (1991). The estimated hardness strength (in transverse and radial surface) and air dry density of the study species are bigger than those of Robinia pseudoacacia as well as Quercia rubra which commercially used in flooring industry. Therefore, the study species is considered compatible for flooring industry.

Conclusion

Wood density, fiber dimensions and hardness strength of the studied species are in the normal range for hardwoods. In general wood basic density and fiber characteristics of the study species are compatible for pulp and paper industries. However, it is recommended to mix the pulp produced from the study species wood with soft-wood or recycled paper pulps to improve their properties. Also their hardness strength as well as air dry density are compatible for flooring industry. The suitability of the study species for such advanced industries would not only reduce imports, but also would provide an economic incentive to the forestry and industrial sectors of Sudan.

References

- Ajala OO, Noah AS (2019) Evaluation of Fibre Characteristics of Aningeria Robusta A. Chev. Wood for its Pulping Potentials. Journal of Forestry Research 16:90-97.

- Ajuziogu GC, Nzekwe U, Chukwuma HI (2010) Assessment of Suitability of Fibres of Four Nigerian Fruit Trees for Paper-Making. Bio-Research 8:679-681.

- Ajuziogu GC, Ojua EO (2020) Comparative Anatomical Studies on the Wood and Bast Fibres of Gmelina arborea. Journal of Materials Science Research and Reviews 5:40-46.

- Andrews FW (1950, 1952, 1956) The Flowering Plants of the (Anglo- Egyptian) Sudan. Vol. 1, 2, and 3. The Burncle of Co., Ltd, Arbroath.

- Anonymous (1984) The Malaysian Grading Rules for Sawn Hardwood Timber (MGR). Malaysian Timber Industry Board, Kuala Lumpur.

- Anonymous (1991) DIN 52 182. Bestimmung der Rohdichte. Deutsches Institut für Normen, über Holz, Bd 31.

- Barnett JR, Jeronimidis G (2003) Wood Quality and its Biological Basis. Blackwell Publishing Ltd. Oxford 226.

- Bendtsen BA (1978) Properties of Wood from Improved and Intensively Managed Trees. Forest Products 28:61-72.

- Bowyer LJ, Shmulsky R, Haygreen GJ (2003) Forest Products and Wood Science: An Introduction, 4th Edition. Blackwell Publishing Company. Iowa 554.

- Broun AF, Massey RE (1929) Flora of the Sudan. Wellington House, London.

- Dutt D, Tyagi, CH (2011) Comparison of various eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian Journal of Chemical Technology 18:145-151.

- Ekhuemelo DO, Tor K (2013) Assessment of Fibre Characteristics and Suitability of Maize Husk and Stalk for Pulp and Paper Production. Journal of research in forestry, wildlife and environmental 5:41-49.

- EL Amin, Hamza M (1990) Trees and Shrubs of the Sudan. Ithaca Press, Exeter.

- IAWA Committee (1989) IAWA list of microscopic features for hardwood identification. IAWA Bull. n.s 10:221-332.

- Ilvessalo-Pfäffli MS (1995) Fiber Atlas, Identification of Papermaking Fibers. Springer-Verlag, Berlin. Germany 400.

- Jane FW (1970) The Structure of Wood. 2nd completely revised by K Wilson and DJB White. London.

- Khristova P, Gabbir S, Bentcheva S, Dafalla S (1997) Soda-AQ pulping of three Sudanese hardwoods, Tropical Sci 37:176-182.

- Khristova P, Gabir S, Bentcheva S, Khider, T (1998) Soda-AQ pulping of four Acacias from Sudan. Cellulose Chemistry and technology 32:299-307.

- Khristova P, Karar I (1999) Soda-anthraquinone pulp form three Acacia nilotica Bioresource Technology 68:209-213.

- Khristova P, Kordsachia O, Dafalla S (2004) Alkaline pulping of Acacia seyal. Tropical Sci 44:207-215.

- Kiaei M, Samariha A (2011) Fiber dimensions, physical and mechanical properties of five important hardwood plants. Indian Journal of Science and Technology 4:1460-1463.

- Lohmann U (1991) Holz Handbuch. 4. völlig überarb. Aufl. DRW Verlag 312.

- Melo JE, Coradin VTR, Mendes JC (1990) Classes de densidade para madeiras da Amazônia Brasileira. Anais do Congresso Florestal Brasileiro 6, vol. 3, Campos do Jordão, São Paulo, Sociedade Brasileira de Silvicultura, São Paulo, SP, Brazil:695-699.

- Ogbonnaya CI, Roy-Macauley H, Nwalozie MC, Annerose DJM (1997) Physical and histochemical properties of kenaf (Hibiscus cannabinus) grown under water deficit on a sandy soil. Ind. Crops Prod 7:9-18.

- Okereke OO (1962) Studies on the fibre dimensions of some Nigerian timbers and raw materials, Part 1. Res. Rep. N°16. Fed. Ministry of Commerce and Industry, Lagos, Nigeria.

- Orwa C, Mutua A, Kindt R, Jamnadass R, Simons A (2009) Agroforestree Database: a tree reference and selection guide version 4.0. Accessed on January 2011, from http://www.worldagroforestry.org/.

- Petri R (1952) Pulping studies with African tropical woods. TAPPI 35:157-160.

- Rydholm SA (1965) Pulping process. In: Wiley and Sons (Eds.), New York, pp. 1270 (reprint from Robert E. Krieger, Malabar, Florida (facsimile edition) (1985).

- Sadiku NA, Abdukareem K A (2019) Fibre morphological variations of some Nigerian guinea savannah timber species. Maderas Ciencia y tecnología 21:239-248.

- Saikia SN, Goswami T, Ali F (1997) Evaluation of pulp and paper making characteristics of certain fast growing plants. Wood Sci. Technol 31:467-475.

- Source1:http://upload.wikimedia.org/wikipedia/commons/c/c6/Sudan_location_map_Topographic.png. Accessed on February 2012.

- Source2:http://www.paperonline.org/paper-making/paper.production/pulping/pulping-properties-of-hardwoods-and-softwood Accessed on January 2011.

- Suliman AM, Jackson JK (1959) The Hegleig Tree. Sudan Silva 9:1-4.

- Thirakul S (1984) Manual of Dendrology, Bahr el Ghazal and Central Regions. Forest Inventory Project Areas. CIDA, Groupe Poulin, Theriault Ltee Consultants, Quebec,Canada 472.

- Tissot M (1985) PapeterieTropicale. Nogent-sur-Marne:CTFT.

- Valkomer PJ (1969) Wood raw materials for pulp paper in tropical countries. FAO International Review of Forestry and Forest Products; Unasylva 23 No.3.

- Ververis C, Georghiou K, Christodoulakis N, Santas P, Santas R (2004) Fiber dimensions lignin and cellulose content of various plant materials and their suitability for paper production. Industrial Crops and Production 19:245-254.

- Vogt K (1995) A Field Guide to the Identification, Propagation and Uses of the Common Trees and Shrubs of Dryland Sudan. SOS Sahel International (UK), London. 309.

- Wagenführ R (1984) Anatomic des Holses VEB, Fachbuchuerlag Leipzig. Germany, 320.

- Wagenführ R (2007) Holzatlas. München: Fachbuchverl. Leipzig im Carl Hanser Verlag 816.

- Xu F, Zhong XC, Sun RC, Lu Q (2006) Anatomy, ultra structure, and lignin distribution in cell wall of Caragana korshinskii. Industrial Crops and Products 24:186-193.